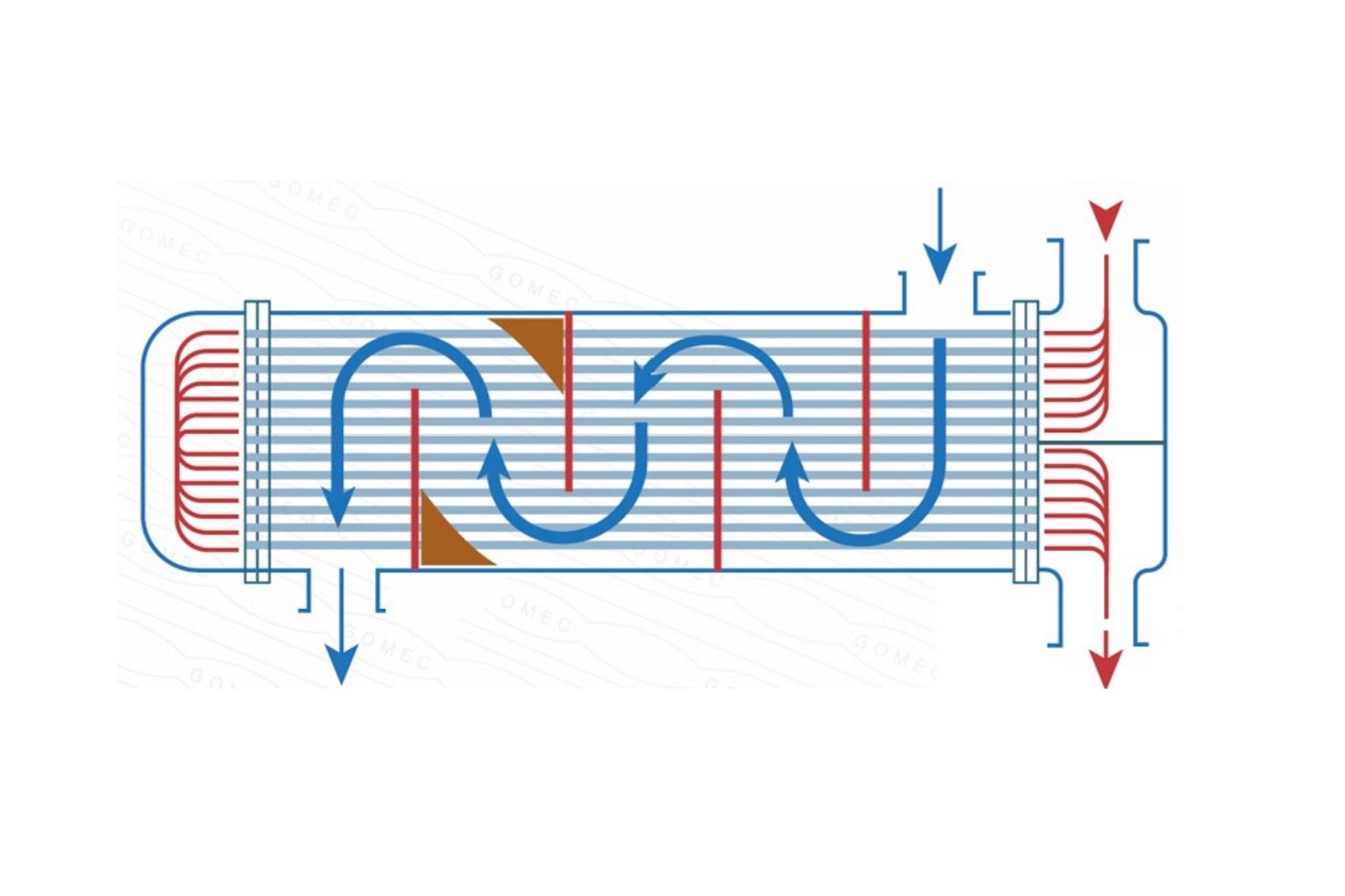

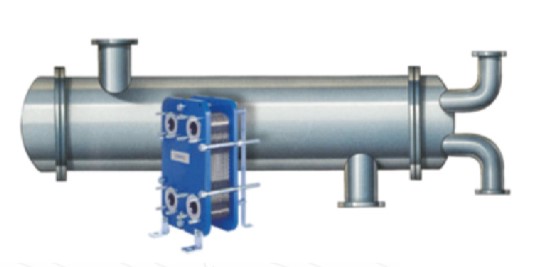

Shell-and-Tube Heat Exchangers: Due to their structural design, counterflow heat exchange is not achieved, resulting in low heat transfer efficiency. Approach temperature typically ranges from 15-20°C. Lower risk of clogging from fibers and impurities. Heavy weight and large installation space required, making maintenance difficult.

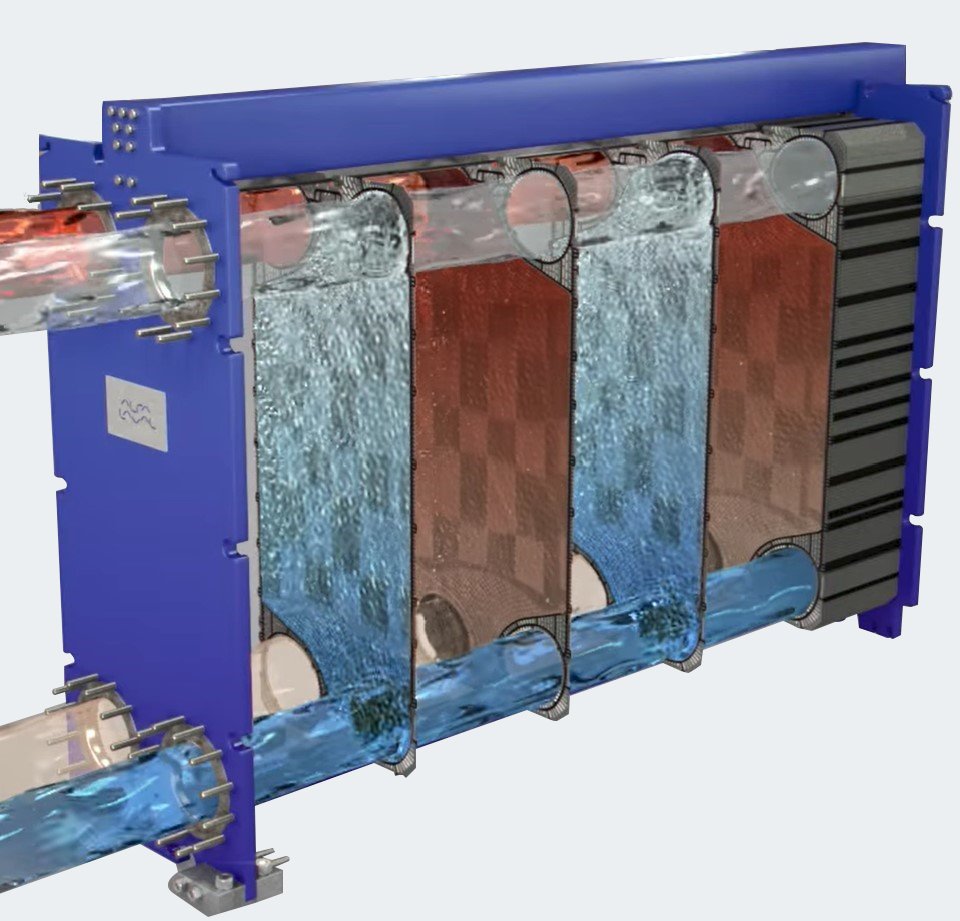

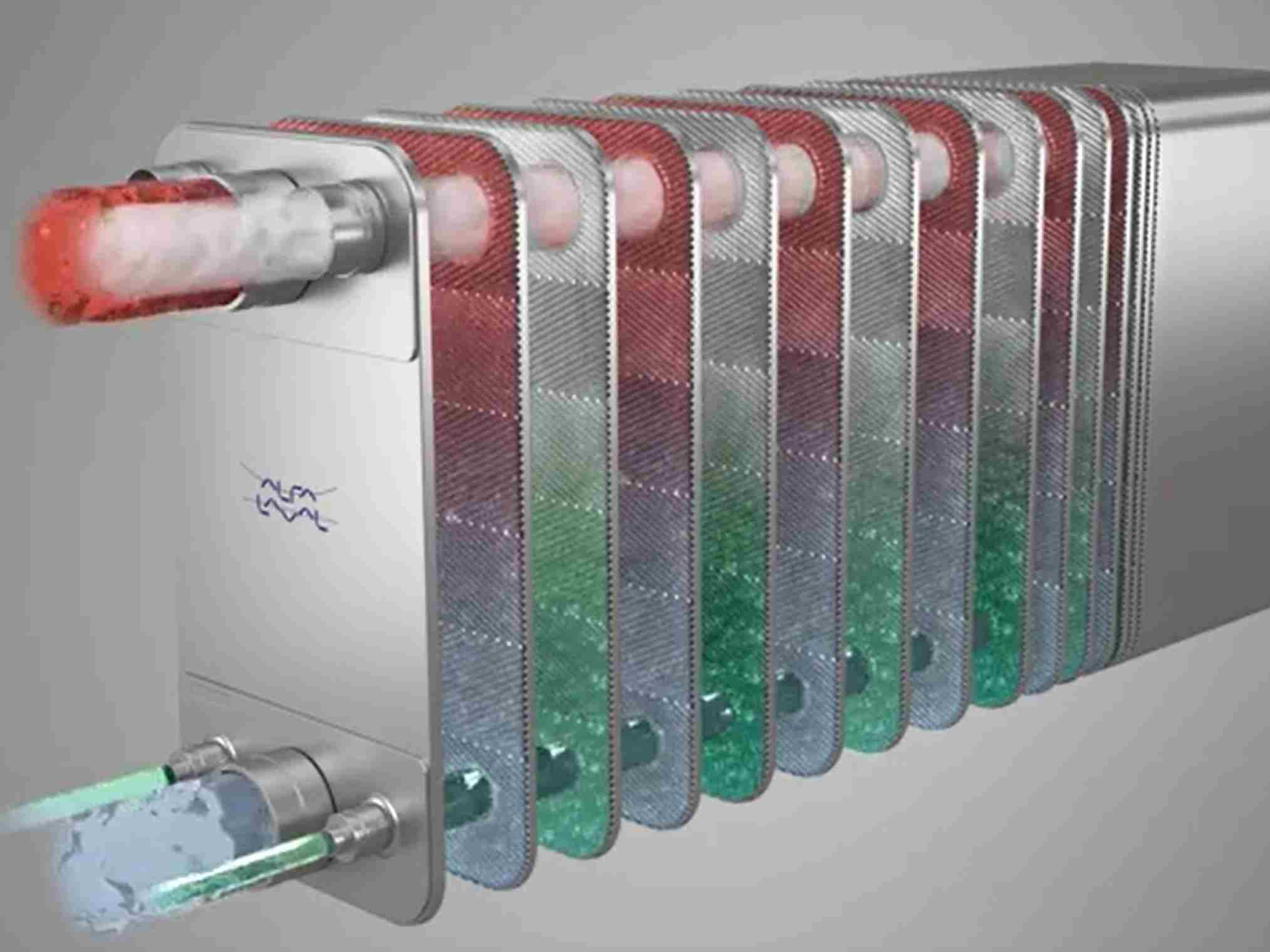

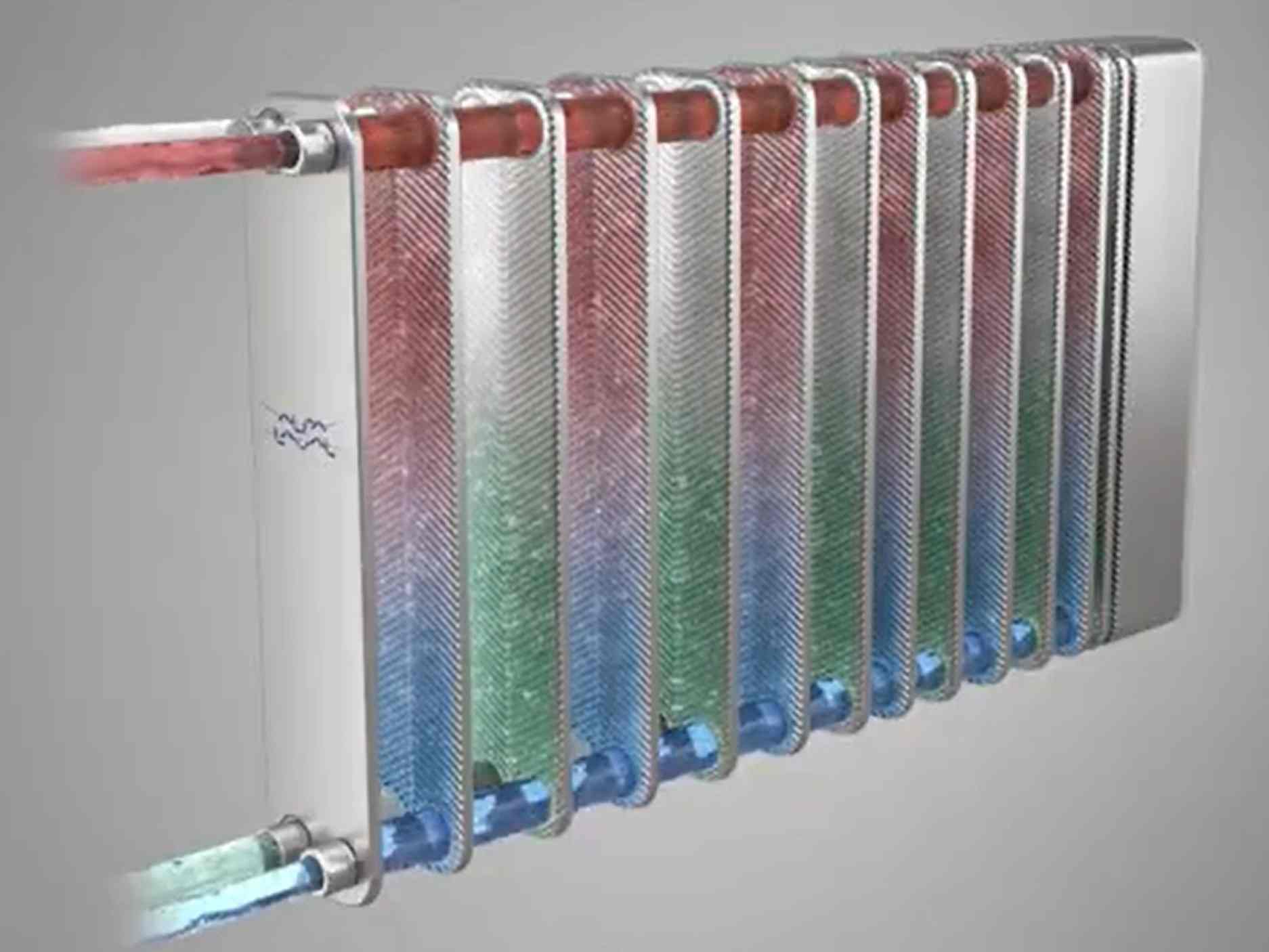

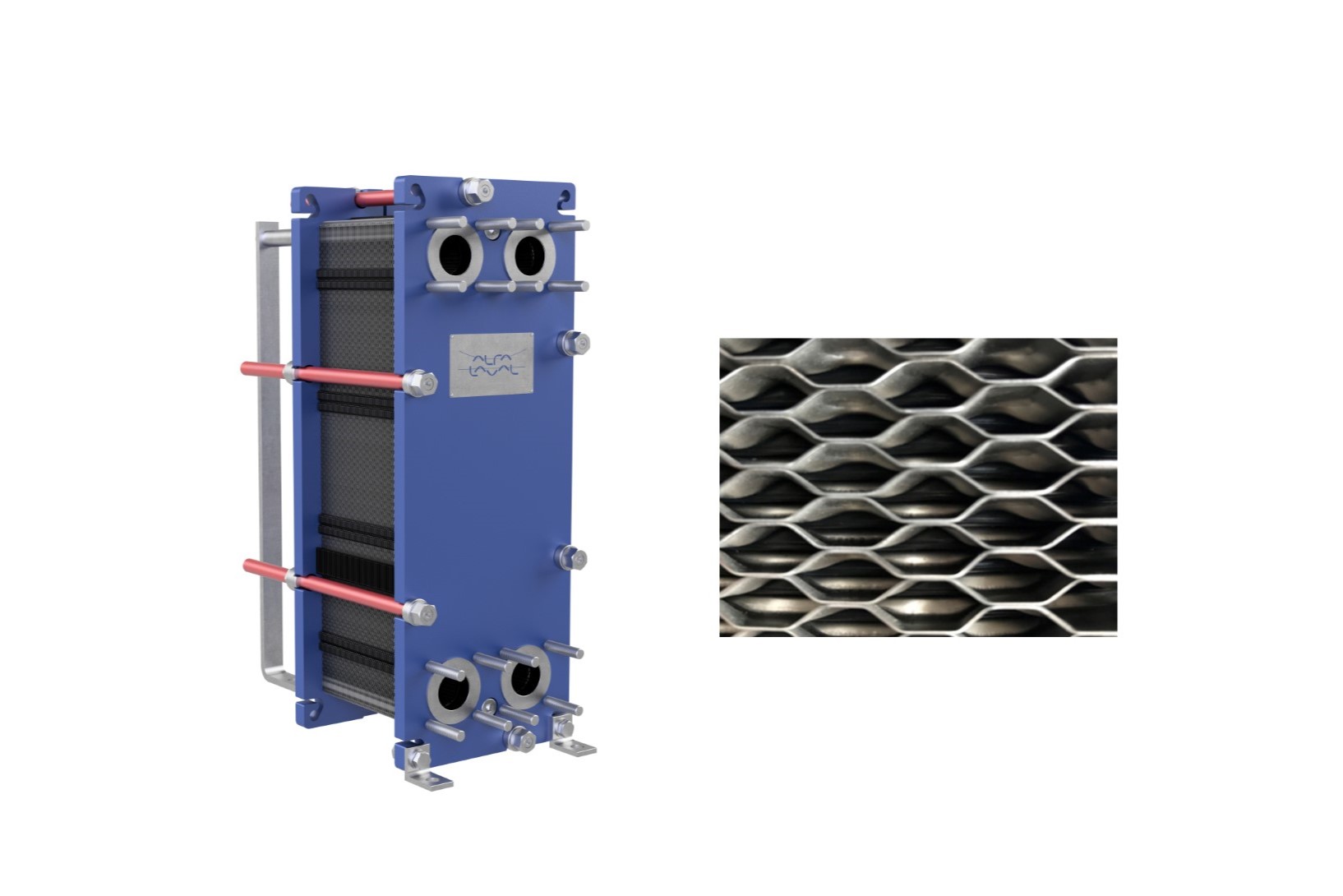

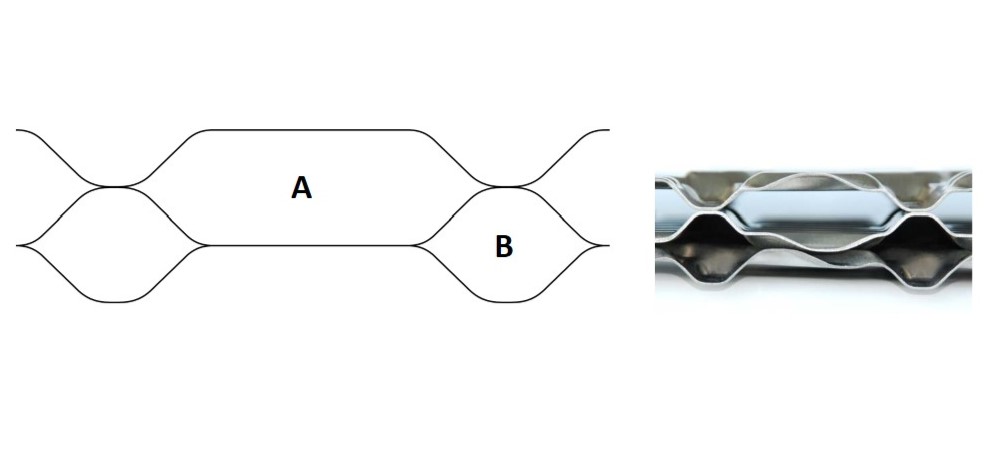

Standard Plate Heat Exchangers (PHE): High heat transfer efficiency, with approach temperatures as low as 1°C. Narrow channel design makes them unsuitable for wastewater with fibers and impurities, leading to frequent clogging.

Rotating Heat Exchangers (Rhex): Open-type heat exchanger, using a motor-driven rotating rotor for heat transfer. Easy maintenance and cleaning. Low heat transfer efficiency, with approach temperatures of ~15°C. High energy consumption due to motor operation. Significant heat loss through convection due to open design. Limited flow rate range (6-36 m³/h). Large footprint and only suitable for outdoor installation with no redundancy options.

These limitations necessitate an advanced, specialized solution to address the unique challenges of industrial wastewater, particularly in textile dyeing plants, where wastewater contains fibers, chemicals, and contaminants.

Leave a Reply