CBM

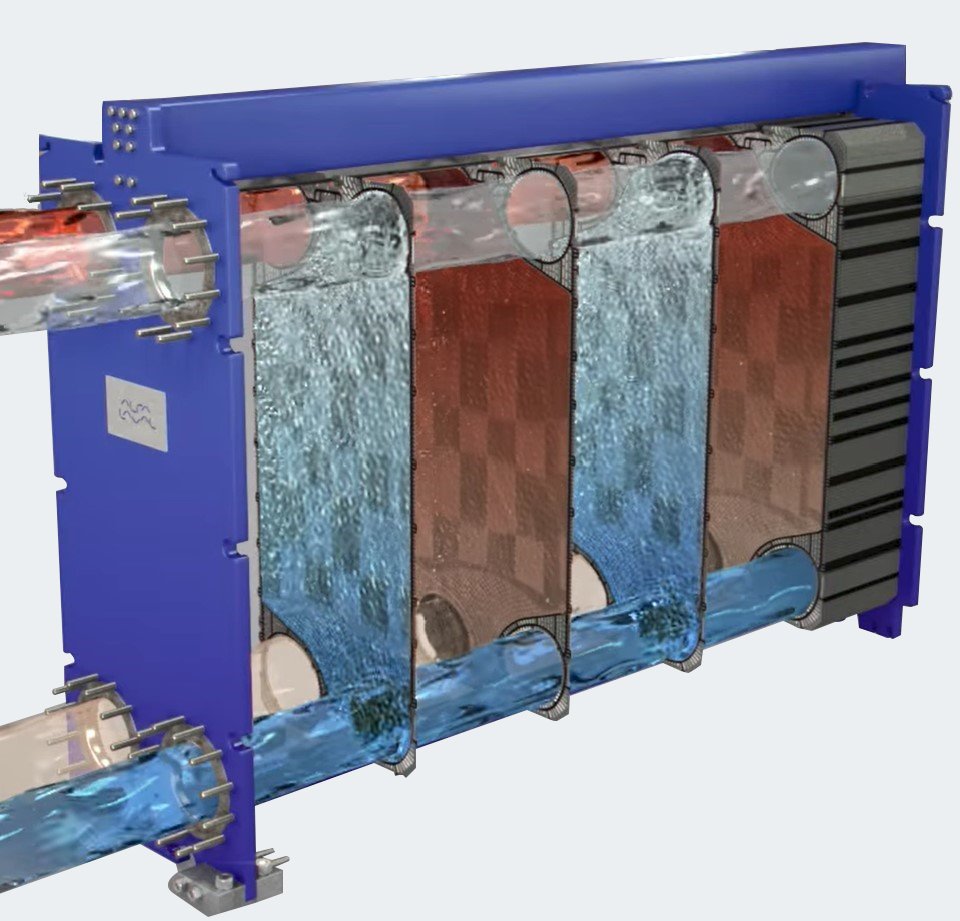

The Alfa Laval CBM line of copper-brazed plate heat exchangers for marine applications offers an ideal solution for demanding installations with limited space. The gasket-free design ensures reliable performance, with stainless-steel plates brazed in a furnace using thin copper foil in between. CBM heat exchangers can be used for duties such as BOG (boil off gas) heating and cooling, natural gas heating, oil heating, heat recovery, refrigeration intercooling and CO2 refrigeration conditioning.

CBM

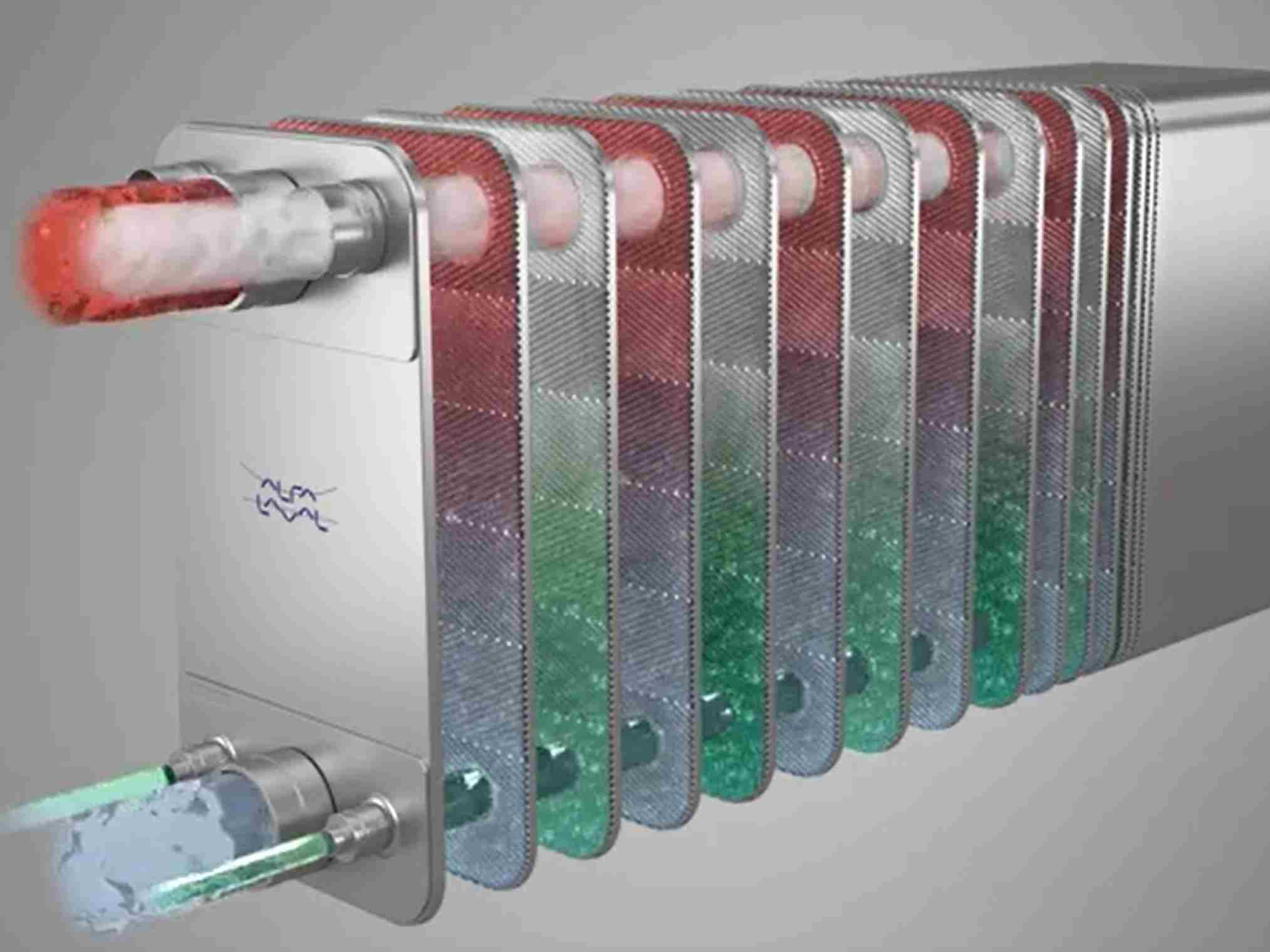

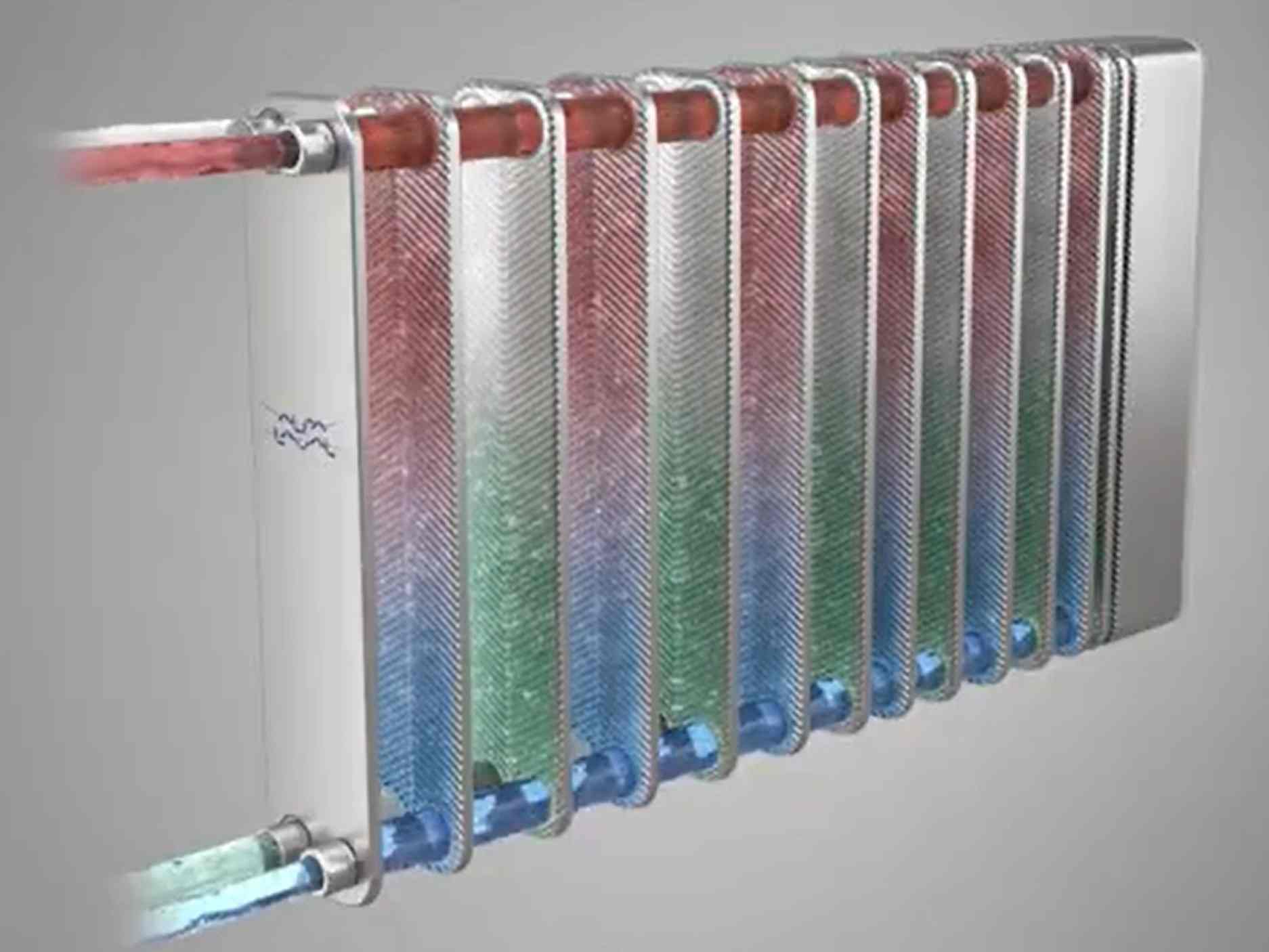

CBM heat exchangers can support design temperatures from cryogenic (-196°C) up to 225°C, at a maximum design pressure of 51 bar. Even higher pressure applications are covered by the AXPM models, which can withstand extreme pressures reaching 159 bar in a temperature range from -45°C to 225°C, due to its reinforced external carbon-steel frame plates.

Heatpac CBM is a predefined range of CBM30 and CBM110 heat exchangers for fuel – and lubrication oil preheating and heat recovery applications. These includes standard insulation and counter flanges with gaskets and bolts.

Robust, compact heat transfer performance

![]() Compact and efficient plate-type heat exchanger

Compact and efficient plate-type heat exchanger

![]() Flexible temperature range from -196°C to +225°C and design pressures up to 159 bar

Flexible temperature range from -196°C to +225°C and design pressures up to 159 bar

![]() Low hold up volume

Low hold up volume

![]() Type-approved by all major class societies

Type-approved by all major class societies

![]() The range includes models: CBM30, CBM110, CBMH200, CBM400, CBM112, ACMH220, and Heatpac CBM

The range includes models: CBM30, CBM110, CBMH200, CBM400, CBM112, ACMH220, and Heatpac CBM

Alfa Laval brazed plate heat exchangers

Please contact GOMEC Vietnam for technical specifications that meet specific design requirements.

| Catalog | Link |

| alfa-laval-cb410-product-leaflet-en | View & Download |

Please contact GOMEC Vietnam for a catalog with models that meet specific design requirements.