AXP AN

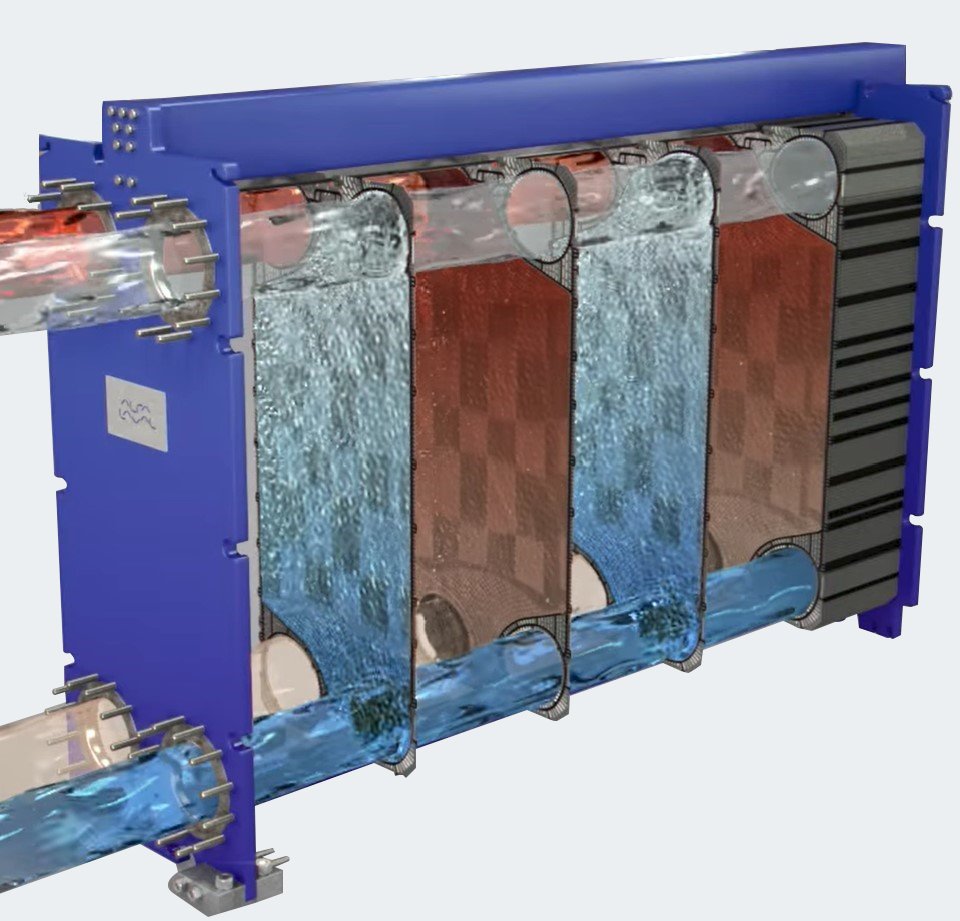

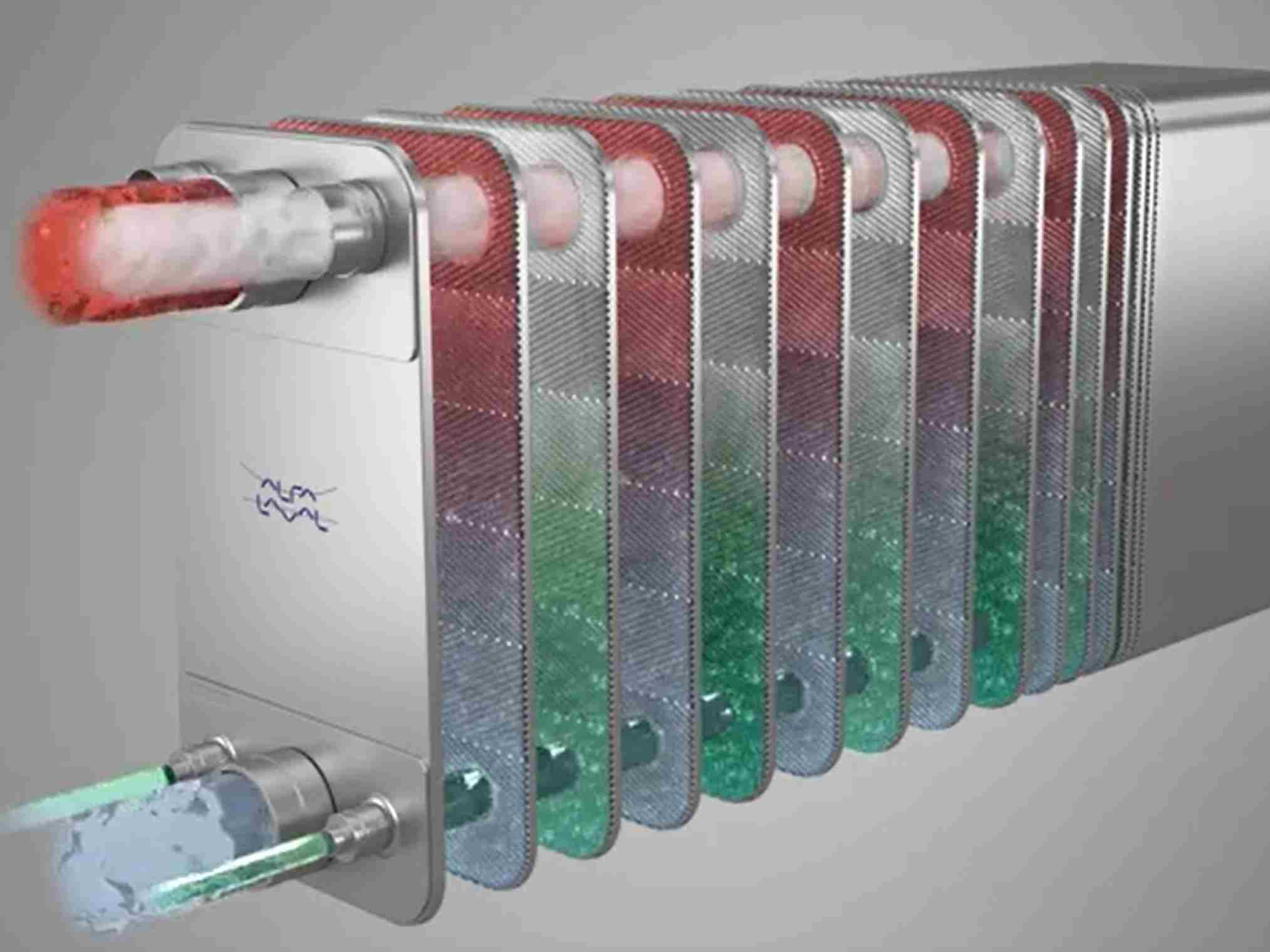

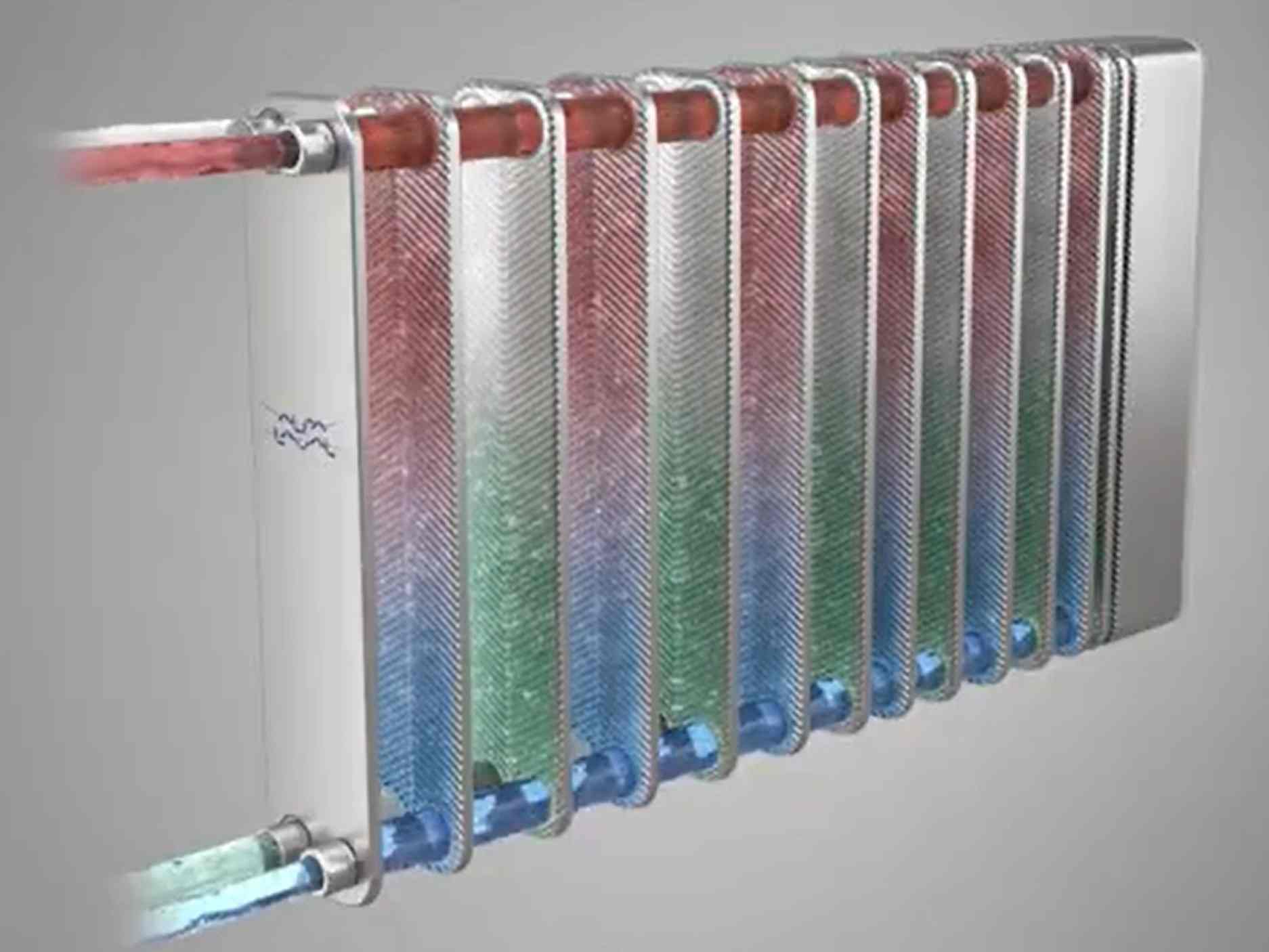

AXP stands for “extreme pressure,” and that’s exactly what this line of AlfaNova heat exchangers are designed to handle. Specifically engineered for subcritical and transcritical applications with CO2, the 100% stainless steel design also enables possibilities for other high-pressure duties with high hygiene demands or aggressive media. AlfaNova is therefore suited to CO2/ammonia cascade systems or compressor cooling.

AXP AN

The AlfaNova AXP line has a capacity range of 10-150 kw, with PED-approval for maximum pressures of 110 bar at 150°C and UL-approval for 1595 psi at 302°F. The high-pressure design, combined with the benefits of Alfa Laval’s all-stainless-steel AlfaFusion bonding process, enable possibilities within a full range of subcritical and transcritical CO2 applications. These include heat recovery duties, gas cooling, condensing, sub-cooling and suction gas heating, and more.

Sustainable Heat Transfer

![]() Highly resistant to corrosion and extreme pressures

Highly resistant to corrosion and extreme pressures

![]() Ensures a low refrigerant volume for ammonia systems where a low charge is desirable

Ensures a low refrigerant volume for ammonia systems where a low charge is desirable

![]() Can reliably support media temperatures ranging from -196°C (-320.8°F) to 550°C (1022°F)

Can reliably support media temperatures ranging from -196°C (-320.8°F) to 550°C (1022°F)

![]() Able to withstand extremely high operating pressures thanks to external frames in carbon steel

Able to withstand extremely high operating pressures thanks to external frames in carbon steel

![]() Certified to handle pressures up to 110 bar (PED approval) and 1595 psi (UL approval)

Certified to handle pressures up to 110 bar (PED approval) and 1595 psi (UL approval)

Alfa Laval AXP AN fusion-bonded plate heat exchanger

Please contact GOMEC Vietnam for technical specifications that meet specific design requirements.

| Catalog | Link |

| alfa-laval-axp-52-an-product-leaflet-en | View & Download |

Please contact GOMEC Vietnam for a catalog with models that meet specific design requirements.

Leave a Reply