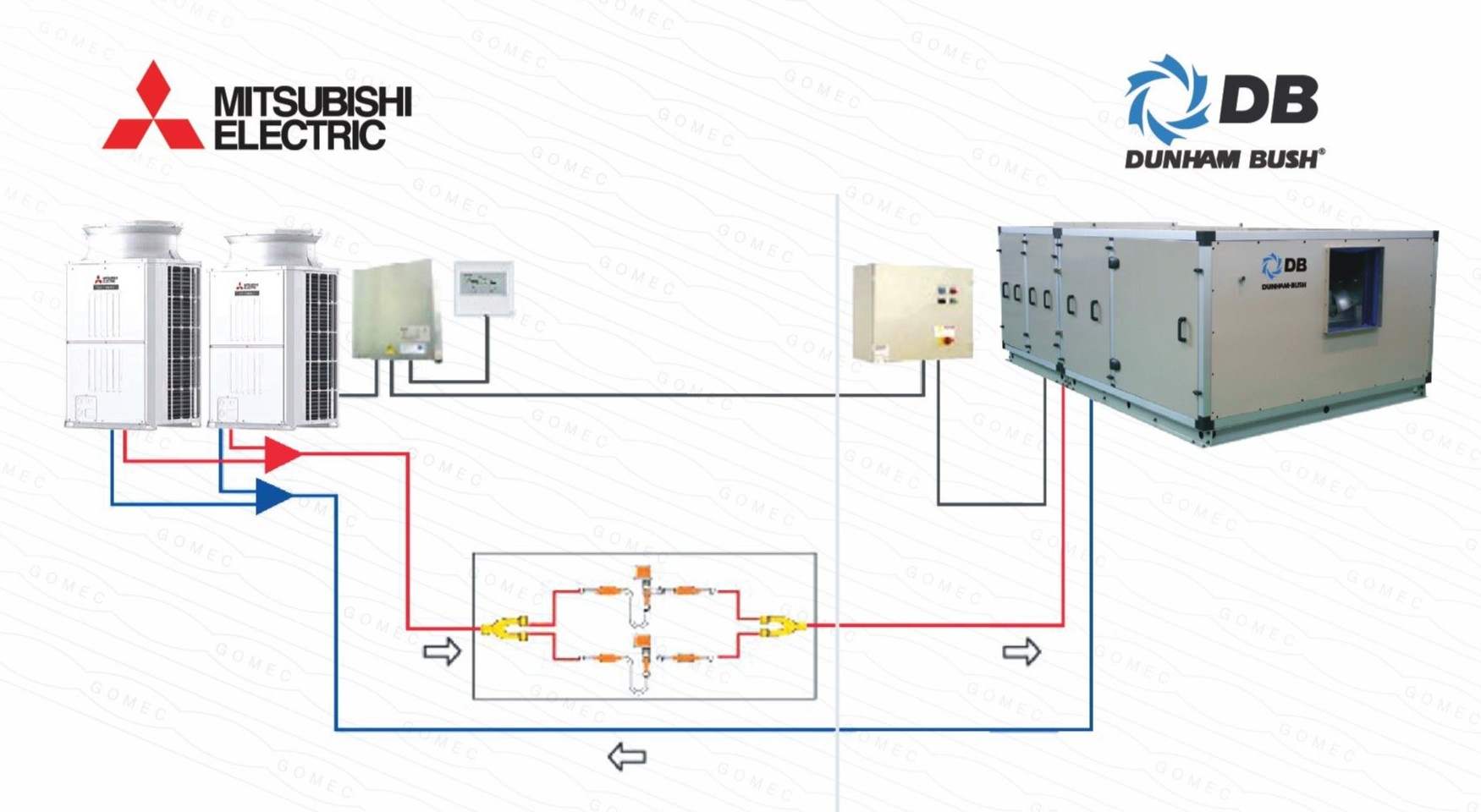

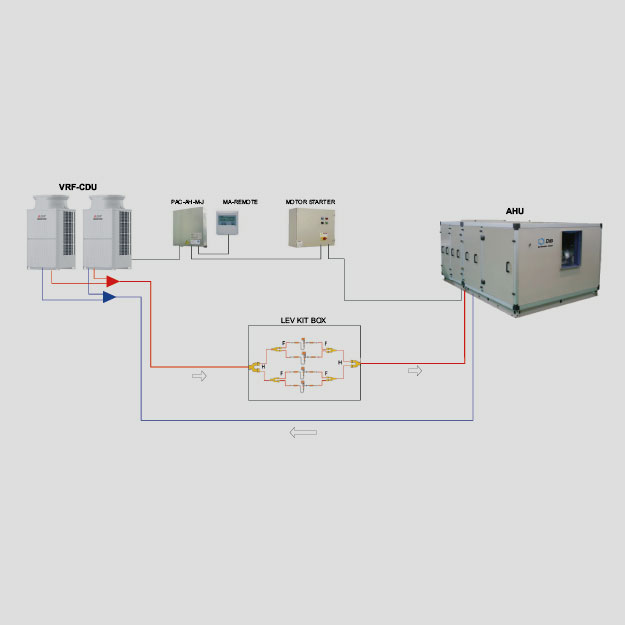

Integrated AHU-DX and CDU-VRF Solution

Contents/ Mục Lục

- 1. Overview of the Solution

- 2. Advantages of the Solution

- 3. Limitations of the Solution

- 4. Applications of the Solution

- 5. Typical Project Implementing the AHU-DX and CDU-VRF Integrated Solution

- 6. Key Considerations for Implementation

- AHU-DX and CDU-VRF Integrated Solution

- ECS3 / ESCS3 Series – Central Station Air Handling Units

Comment

Login

0 Comments

oldest