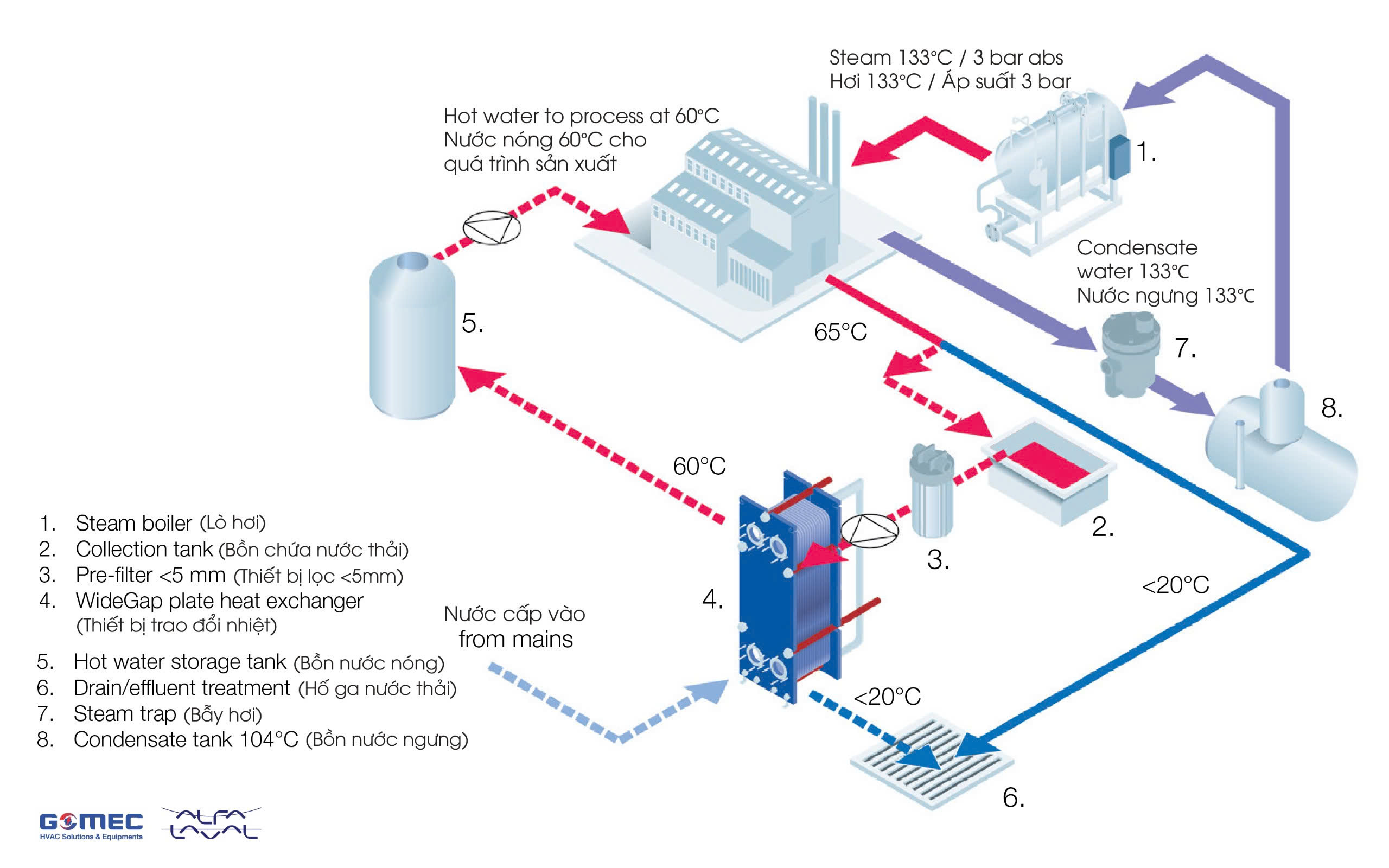

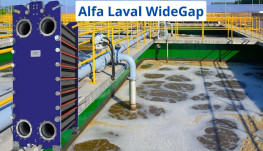

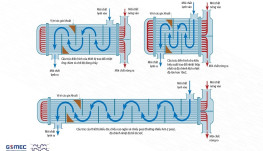

Heat Recovery From Warm Wastewater Solution

Contents/ Mục Lục

Comment

Login

0 Comments

oldest