FHE introduction

Contents/ Mục Lục

- 1. Construction of a fusion-bonded plate heat exchanger

- 2. How a fusion-bonded plate heat exchanger works

- 3. When to choose a fusion-bonded plate heat exchanger

- 4. Why choose a fusion-bonded plate heat exchanger from Alfa Laval?

- 5. Different product lines for different needs

- 6. Fusion-bonded plate heat exchangers (FHE) product lines

- AlfaNova

- AlfaNovaM

- AlfaNovaTW

- AXP AN

- AlfaNova GL

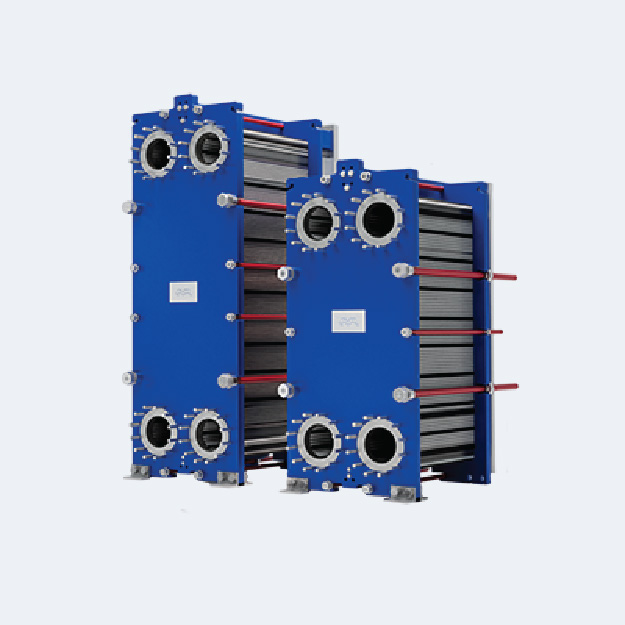

1. Construction of a fusion-bonded plate heat exchanger

Inside of a fusion-bonded plate heat exchanger

Alfa Laval AlfaNova fusion-bonded heat exchanger consists of corrugated stainless steel plates, a frame plate and a pressure plate. The heat transfer plates in the plate pack are bonded together using AlfaFusion technology, a unique method of bonding stainless steel components which is an Alfa Laval patent.

The fusion bonded design holds the plate pack together internally with contact points. Distributing the load across many separate contact points provides excellent resistance to pressure fatigue. Because the product is made from 100% stainless steel, this design is thermally efficient as well as being shock-proof and having a mechanical strength fully equivalent to any welded counterpart.

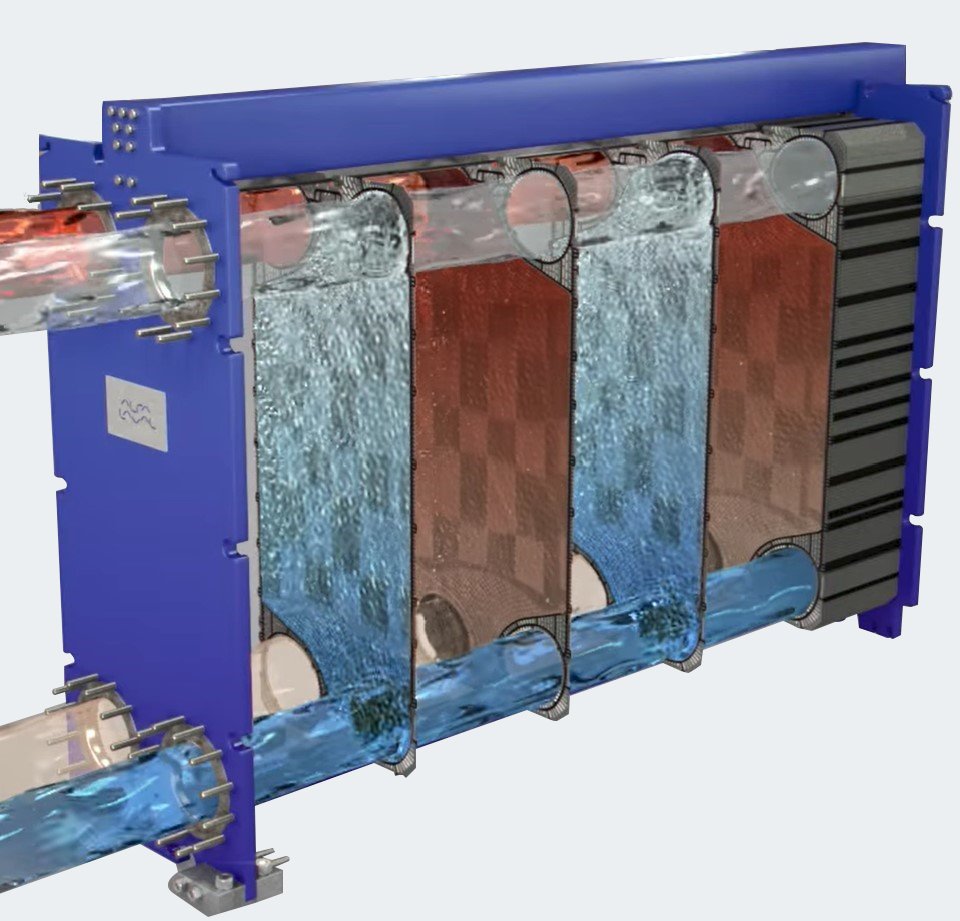

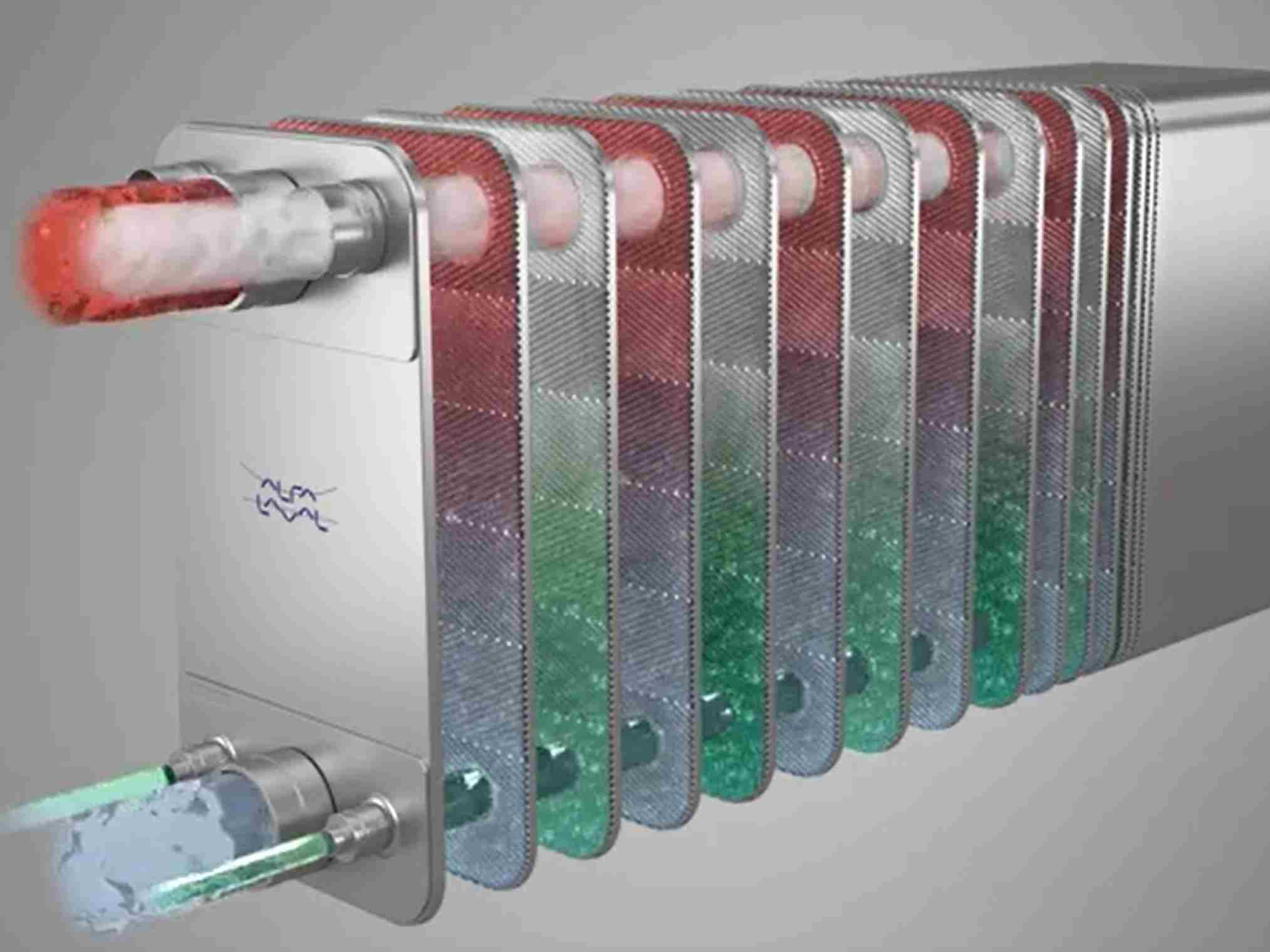

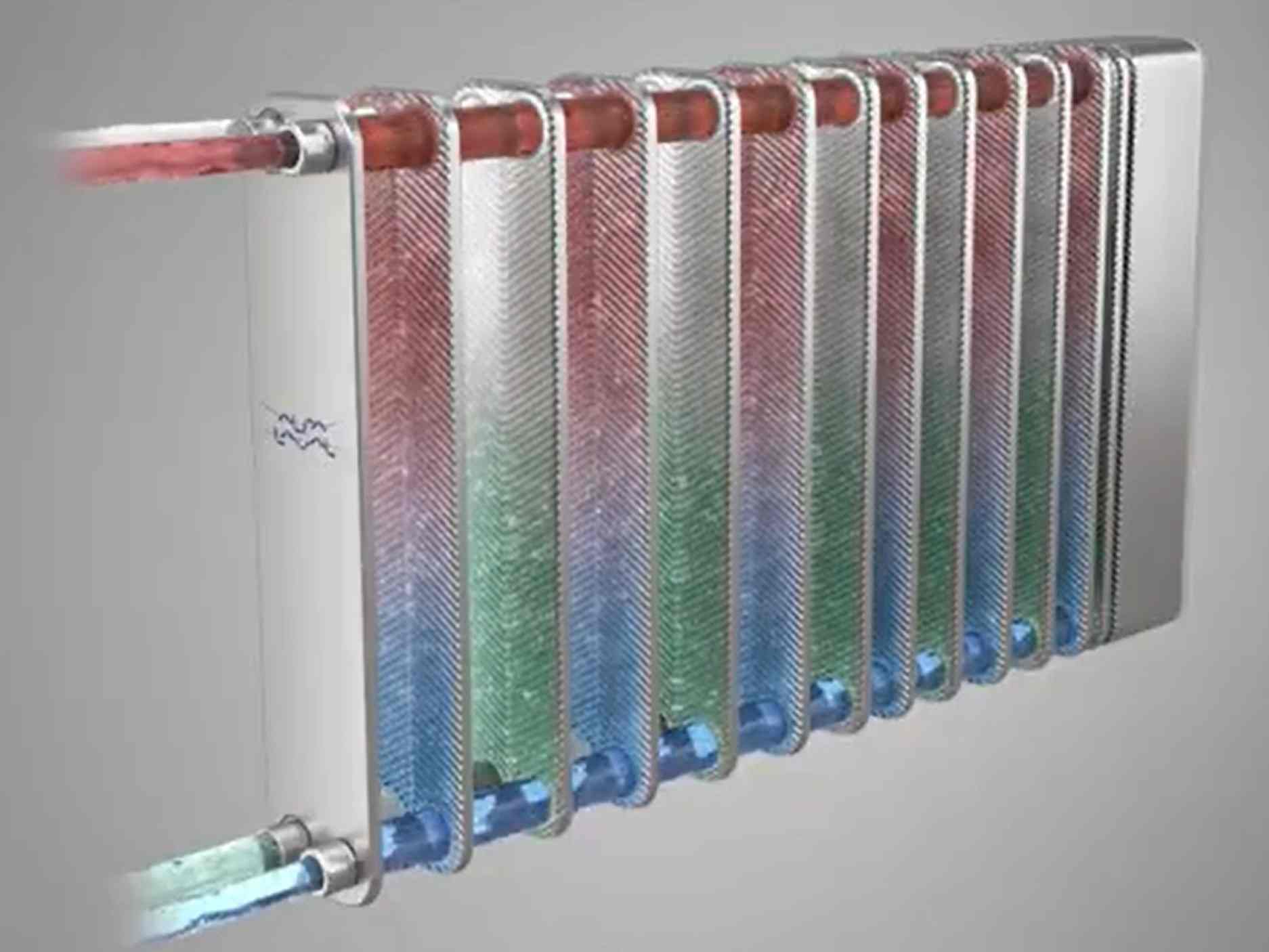

The heat exchanger works on the basis of two media at different temperatures flowing on either side of thin corrugated stainless steel plates stacked on top of each other.

The design of the channels between the plates, along with entry and exit ports placed in the corners, means that the two media flow through alternate channels, normally in counter-current flow. The media are kept within the plate pack by a fusion-bonded seal around the edge of the plates. The points at which the plates are in contact with each other are also bonded using the same technology, reinforcing the pack against the pressure of the media inside.

The counter-current flow makes it possible to extract heat efficiently even when there are only extremely small differences between the temperatures of the hot and cold media. This results in notable savings on energy costs.

2. How a fusion-bonded plate heat exchanger works

Liquid-Liquid flow animation

Condenser flow Animation

Evaporator flow animation

3. When to choose a fusion-bonded plate heat exchanger

Fusion-bonded plate heat exchangers can be used for most purposes and in most industries.

When you have limited space

Fusion-bonded plate heat exchangers are very compact since no frame or gaskets are needed. The design consists solely of surfaces that actively contribute to heat transfer, resulting in significant increases in overall efficiency. That gives it high heat transfer efficiency relative to its small footprint.

When you want to avoid maintenance

The fusion-bonded plate heat exchanger is gasket free. It is also designed to create high turbulence which results in a self-cleaning effect. That’s why it requires minimal maintenance.

When you need extremely high temperature or high pressure

The portfolio of fusion-bonded plate heat exchangers can handle different levels of maximum design pressures – up to 110 bar/1595 psi, and handles temperatures from -196°C up to 550°C (–320.8°F up to 1022°F)

When you want simple selection

Choosing and configuring a fusion-bonded plate heat exchanger for the duty is simple with easy-to-use selection tools.

When copper is not allowed

In some installations copper is not allowed and at the same time there is a demand on small footprint.

When metal leaching should be minimized

Compared to competing technologies e.g. nickel brazing the release of metals like nickel are exceptionally low. A fusion-bonded plate heat exchanger is made from 100% stainless steel and is thus not adding any nickel to the final product.

In some cases, a fusion-bonded plate heat exchanger is not the most suitable choice

When district heating water quality is poor

Since the fusion-bonded plate heat exchanger is not openable, it is not suitable when there is a risk of fouling or clogging. In these cases, a gasketed plate heat exchanger is the more appropriate choice.

When you have corrosive fluids

The fusion-bonded plate heat exchanger is made from stainless steel. It cannot withstand fluids which are corrosive to the stainless steel itself. If you have sea water, corrosive water or something similar, you need a gasketed plate heat exchanger made from another plate material (for example titanium).

When you need extremely high capacity

The size of fusion-bonded plate heat exchangers is limited. If you need extremely high capacity (decided by the duty), a gasketed plate heat exchanger may be a better fit.

4. Why choose a fusion-bonded plate heat exchanger from Alfa Laval?

What sets one fusion-bonded plate heat exchanger apart from another? Let’s look at the features of Alfa Laval’s range that create extra value.

PressureSecure: Secure a small footprint even if you have demanding duties with high temperature and pressure applications

Drawing on our deep knowledge of plate design, our units use thinner plates and fewer of them – but still support the widest range of high temperature and high-pressure applications. This results in less raw material use, lower energy consumption, reduced refrigerant charge and a longer equipment lifecycle.

We call this design PressureSecure.

When you need products for natural refrigerant applications

REFuture: Our fusion-bonded plate heat exchangers enable the use of new-generation and low-GWP refrigerants to help meet sustainability goals and legislative requirements.

We call this REFuture.

IceSafe: Secure reliable performance in applications with a risk of freezing

In some applications and duties, ice crystals can form in the heat exchanger. This creates a risk of freezing which can leave you with a broken heat exchanger. When required, Alfa Laval can supply plate heat exchangers designed to allow ice crystals to form under certain operating conditions, but displaced from sensitive areas. This ensures both reliable performance and a long product life.

We call it IceSafe.

ValuePlus: Much more than a heat exchanger

Do you want to tailor and do a test run of your product before buying a larger batch? You can rely on our prototyping expertise. Do you appreciate fast delivery, easy installation and optimization, and full compliance with regulations? You can rely on our testing expertise and our large-scale manufacturing capabilities. On top of this, you gain access to a wide range of tools and support, including all documentation, approvals and certifications as well as an ever-expanding range of accessories.

We call this ValuePlus.

100% stainless steel: Built with 100% stainless steel, AlfaNova® is a solution that Alfa Laval offers for applications that use media not compatible with traditional heat exchanger materials. Not only is this advanced design optimized for use with natural refrigerants, it’s also completely recyclable.

5. Different product lines for different needs

The Alfa Laval AlfaNova are suited in applications which put high demand on cleanliness, applications where aggressive medias like ammonia are used or where copper and nickel contamination is not accepted. AlfaNova heat exchangers are used in applications such as: HVAC heating/cooling, refrigeration, process heating/cooling and oil cooling. The AlfaNova line has an extreme pressure fatigue resistance and covers high temperatures.

The Alfa Laval AlfaNova AQ range of fusion-bonded plate heat exchangers for HVAC applications is AHRI Certified® through the Liquid to Liquid Brazed & Fusion-bonded Plate Heat Exchangers (LLBF) Certification Program which ensures the thermal performance in accordance to the product specifications.

The Alfa Laval AlfaNova M Marine line comprises fusion-bonded plate heat exchangers made of 100% stainless steel, used for a wide range of aggressive media or high temperatures. Typical applications are Liquefied Petroleum Gas/Ethylene (LPG/E) re-liquefication including ammonia and Liquefied Natural Gas (LNG) fuel duties. AlfaNova M can be provided with marine approvals from all major societies.

AlfaNova X-treme Pressure line (Alfa Laval AXP AN) is specially developed for high pressure applications with requirements for 100% stainless steel, for example high pressure ammonia systems or compressor cooling.

Alfa Laval RM Recuperator is a 2-port fusion-bonded plate heat exchanger made of 100% stainless steel. It is specifically designed for heat recovery from exhaust gas and separation of condensed water.

Learn more about characteristics of each product line by clicking the link below:

Manufactured with Alfa Laval’s patented AlfaFusion technology, AlfaNova is a heat exchanger consisting of corrugated stainless steel plates bonded together without any copper or nickel. The unique design means that AlfaNova can withstand more extreme temperatures (up to 550°C/1022°F) and pressures with greater fatigue resistance than conventional brazed plate heat exchangers. It is also suitable for duties with very high hygiene demands.

The AlfaNova product line also includes AlfaNova AQ and AlfaNova M with different design pressure levels to fit different types of fluids and applications. This makes the product line ideal for applications where temperatures and pressures can be high. For example, district heating, heat pumps and a wide range of heating, cooling and tap water solutions.

Alfa Laval fusion-bonded plate heat exchangers can be supplied with various accessories and extras:

Insulation might be needed for cooling or heating when you want to minimize energy loss and for staff safety.

Couplings and counter flanges can make it easy to install the AlfaNova. A large number of sizes and types are available to fit various installations.

Feet and support kits can make it easier to install the AlfaNova and ensure it is not exposed to high outer forces by hanging on the pipes and connections.

Units in the AlfaNova product line are available in many different sizes and capacities with varying plate patterns and connections for particular duties and performance specifications.

Manufactured with Alfa Laval’s patented AlfaFusion technology, AlfaNova is a heat exchanger consisting of corrugated stainless steel plates bonded together without any copper or nickel. The unique design means that AlfaNova can withstand more extreme temperatures (up to 550°C/1022°F) and pressures with greater fatigue resistance than conventional brazed plate heat exchangers. It is also suitable for duties with very high hygiene demands.

The AlfaNova product line also includes AlfaNova AQ and AlfaNova M with different design pressure levels to fit different types of fluids and applications. This makes the product line ideal for applications where temperatures and pressures can be high. For example, district heating, heat pumps and a wide range of heating, cooling and tap water solutions.

Alfa Laval fusion-bonded plate heat exchangers can be supplied with various accessories and extras:

Insulation might be needed for cooling or heating when you want to minimize energy loss and for staff safety.

Couplings and counter flanges can make it easy to install the AlfaNova. A large number of sizes and types are available to fit various installations.

Feet and support kits can make it easier to install the AlfaNova and ensure it is not exposed to high outer forces by hanging on the pipes and connections.

Units in the AlfaNova product line are available in many different sizes and capacities with varying plate patterns and connections for particular duties and performance specifications.

The Alfa Laval AlfaNova AQ range of fusion-bonded plate heat exchangers for HVAC applications is AHRI Certified® through the Liquid to Liquid Brazed & Fusion-bonded Plate Heat Exchangers (LLBF) Certification Program which ensures the thermal performance in accordance to the product specifications.

They are suitable for a wide range of applications, such as HVAC and industrial heating/cooling and refrigeration.

Alfa Laval fusion-bonded plate heat exchangers can be supplied with various accessories and extras.

Insulation is needed for cooling to minimized energy loss and to prevent ice build-up.

Couplings and counter flanges can make it easy to install the AlfaNova AQ. A large number of sizes and types are available to fit various installations.

Feet and support kits make it easier to install the AlfaNova AQ and ensure it is not exposed to high outer forces by hanging on the pipes and connections.

Units in the AlfaNova AQ product line are available in many different sizes and capacities with varying plate patterns and connections for particular duties and performance specifications

AlfaNovaM Marine line comprises fusion-bonded plate heat exchangers made of 100% stainless steel, used for a wide range of aggressive media or high temperatures (working range from -196°C/-321°F to 550°C/1022°F). Typical applications are Liquefied Petroleum Gas/Ethylene (LPG/E) re-liquefication including ammonia and Liquefied Natural Gas (LNG) fuel duties. AlfaNovaM can be provided with marine approvals from all major societies.

Units in the AlfaNovaM product line are available in two different sizes; AlfaNovaM 76 and AlfaNovaM 400.

Alfa Laval fusion-bonded plate heat exchangers can be supplied with various accessories and extras:

Insulation is needed for cooling to minimized energy loss and to prevent ice build-up.

Couplings and counter flanges can make it easy to install the AlfaNovaM. A large number of sizes and types are available to fit various installations.

Feet and support kits make it easier to install the AlfaNovaM and ensure it is not exposed to high outer forces by hanging on the pipes and connections.

AlfaNova X-treme Pressure line is specially developed for high pressure applications with requirements for 100% stainless steel, for example high pressure ammonia systems or compressor cooling. The max working pressure within the AlfaNova X-treme Pressure line is 110 bars/1595 PSI.

Because of their high-pressure performance, they are particularly well-suited to CO2 applications, such as transcritical gas cooling. AlfaNova X-treme pressure line is specially designed to fulfill the need when using R744/CO₂ as refrigerant in subcritical and transcritical applications and for high pressure applications with requirements for 100% stainless steel.

The Alfanova X-treme pressure line is suitable to cover heat recovery duties, gas cooling, condensing, sub-cooling and suction gas heating.

AXP AN are fusion-bonded plate heat exchangers with thin external frames in carbon steel that are able to withstand extremely high operating pressures.

Units in the AXP AN product line are available in two different sizes; AXP27 AN and AXP52 AN.

Insulation is needed for cooling to minimized energy loss and to prevent ice build-up.

Couplings and counter flanges can make it easy to install the AlfaNova AXP AN. A large number of sizes and types are available to fit various installations.

Feet and support kits make it easier to install the AlfaNova AXP AN and ensure it is not exposed to high outer forces by hanging on the pipes and connections

AlfaNova GL50 is a high-efficiency heat exchanger for the most demanding gas-to-liquid applications. Featuring our patented AlfaFusion technology, the AlfaNova GL50 can increase efficiency and minimize energy loss in fuel cells and other systems. Highly robust and compact enough to hold in one hand, it does the job with very low pressure drop. Its ability to condense water vapor makes it ideal for use in systems where fuels such as ammonia or methanol require reforming.

6. Fusion-bonded plate heat exchangers (FHE) product lines

Reference:

- Find out more about the Alfa Laval gasketed plate heat exchangers (GPHE)

- Find out more about the Alfa Laval brazed plate heat exchangers (BHE)

- AHRI Performance Certification – Why Is It Necessary?

- project@gomec.vn

- Hotline & Zalo 0379 586 886

- (+84) 024 3200 8920

- Gomec Vietnam

- Gomec Vietnam