Alfa Laval Heat Exchangers: Versatile Applications and Energy Efficiency

Contents/ Mục Lục

In modern industrial sectors, energy efficiency and conservation are top priorities. Alfa Laval heat exchangers provide a reliable solution to meet the stringent demands of industrial applications. With advanced design and superior quality, Alfa Laval heat exchangers deliver high thermal performance. Additionally, they contribute to reducing operational costs and environmental impact. Let’s explore Alfa Laval heat exchangers in greater detail in this article.

1. What is a Heat Exchanger?

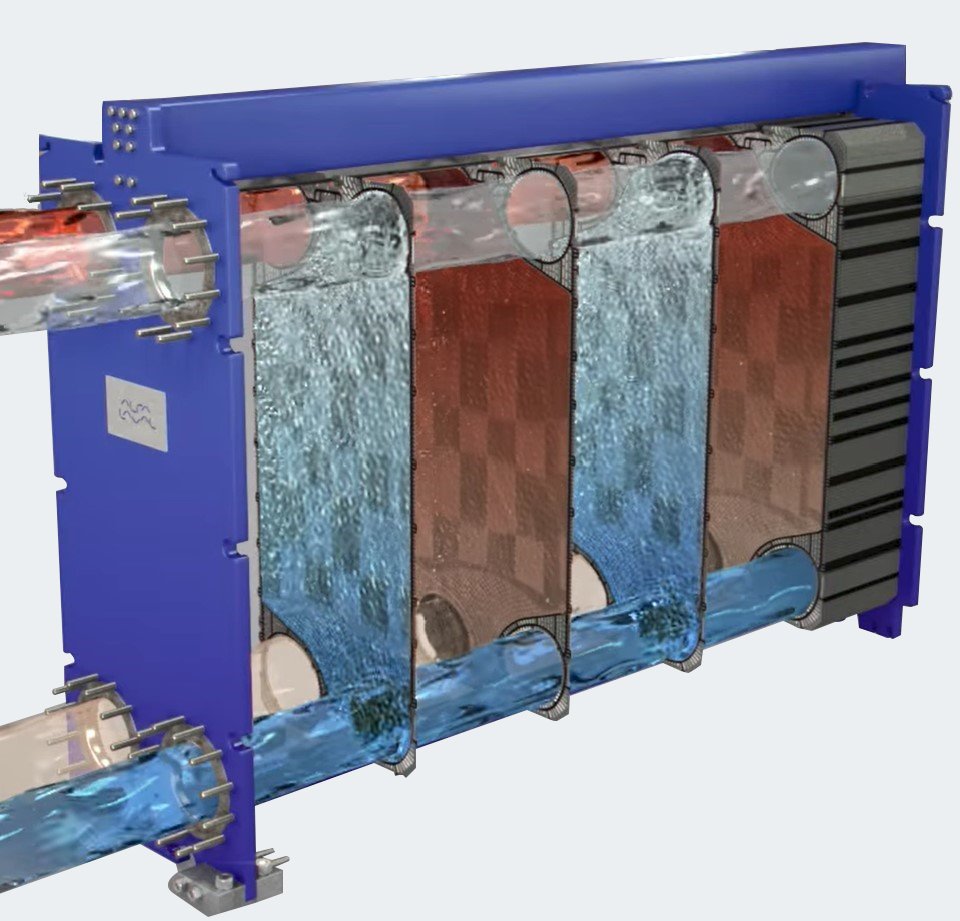

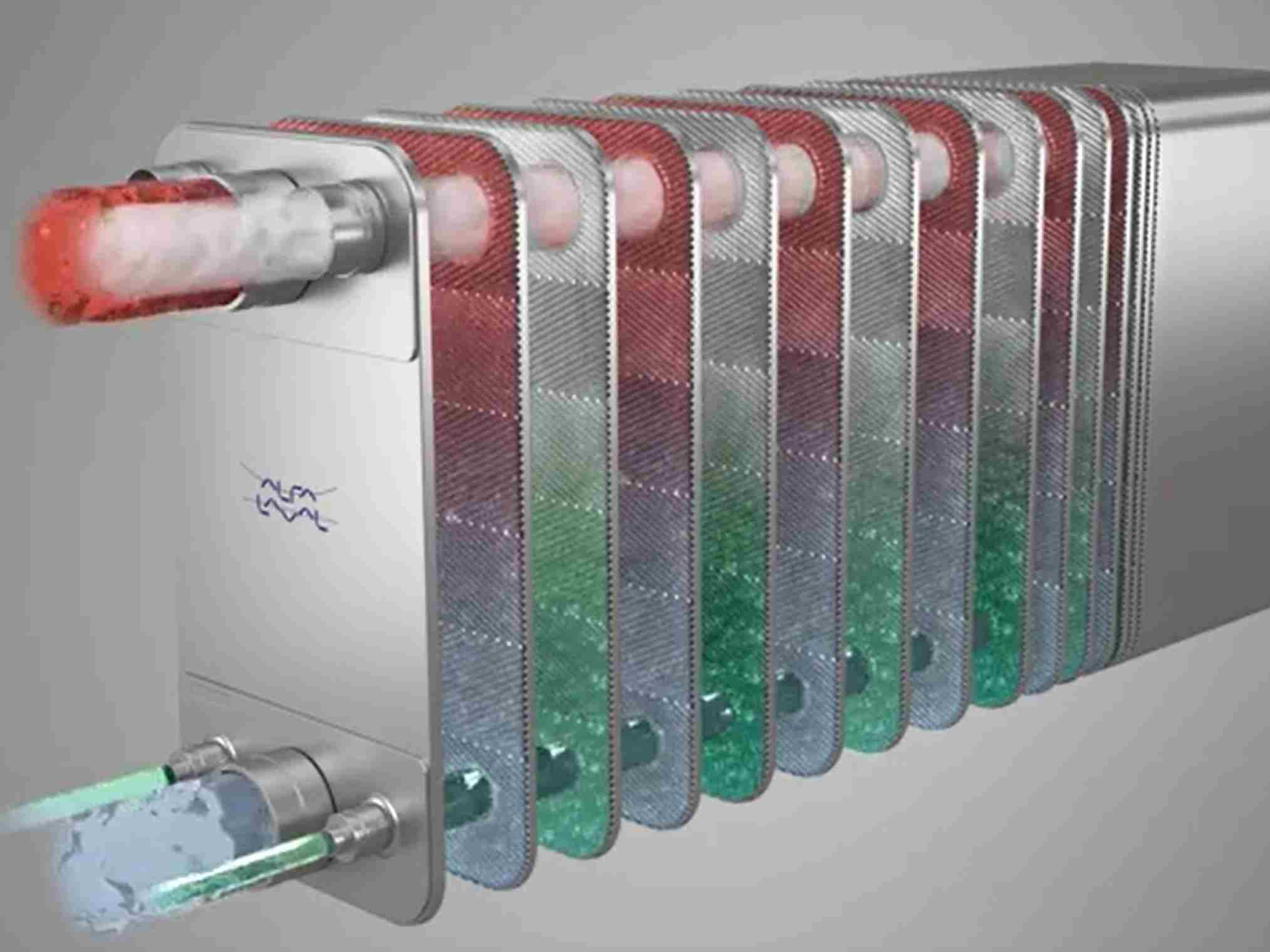

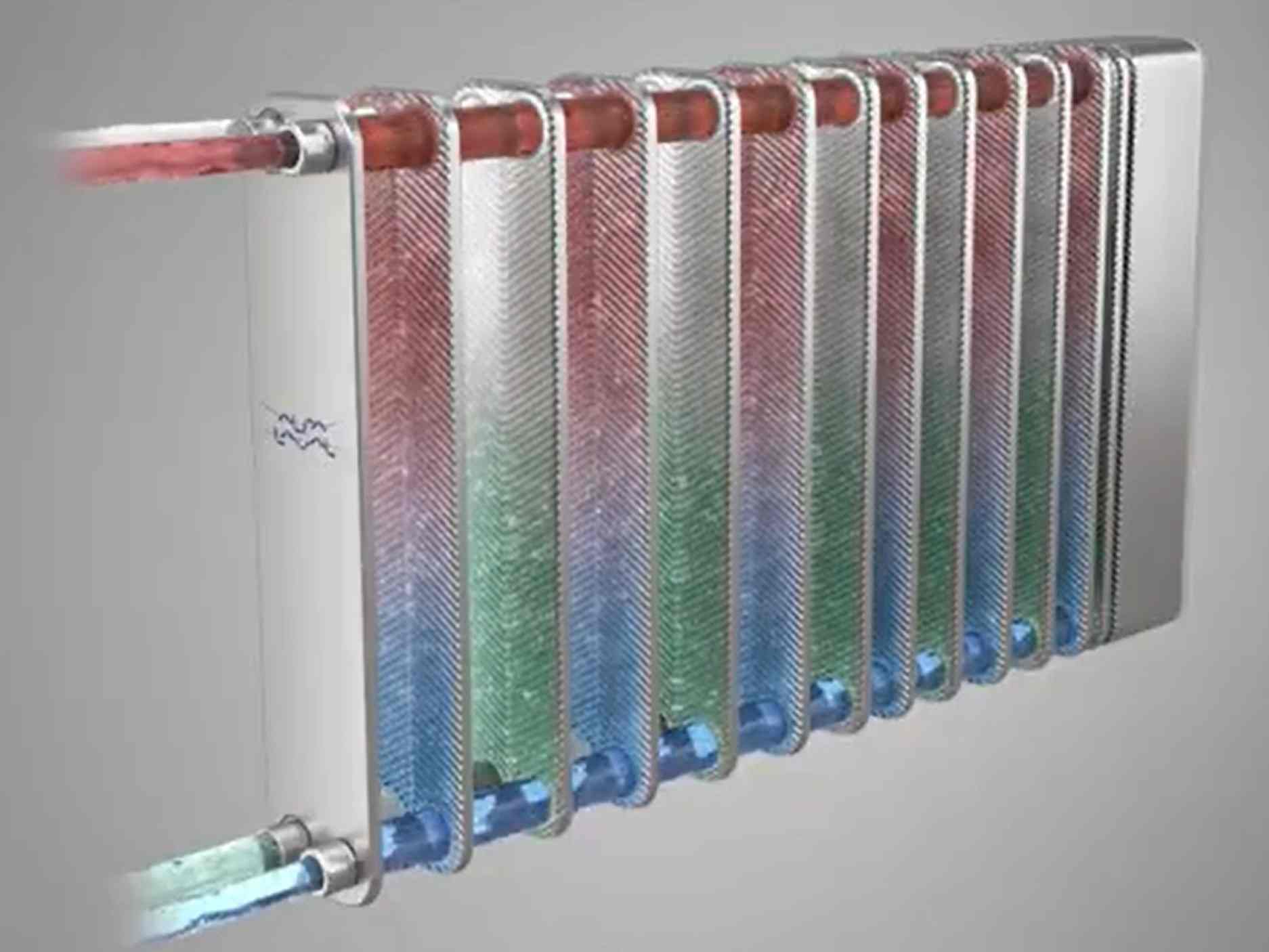

A heat exchanger is a device used to transfer heat between two different media at different temperatures without direct contact between them.

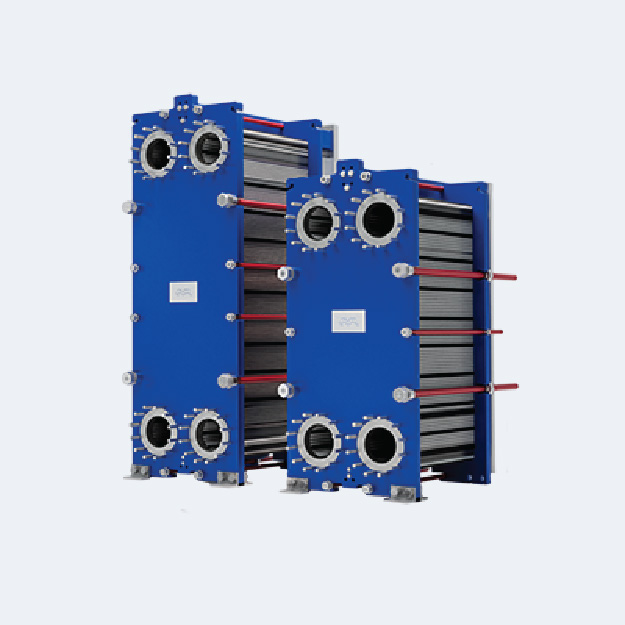

Alfa Laval heat exchangers are typically designed with thin, embossed metal plates. These plates are assembled using gaskets or welded connections. With a diverse range of plate structures and materials, Alfa Laval heat exchangers are widely applied in industrial and commercial sectors today.

2. Why Choose Alfa Laval Heat Exchangers?

Alfa Laval is one of the world’s leading manufacturers of heat exchangers. Headquartered in Sweden, Alfa Laval operates globally with offices, production facilities, and distribution networks worldwide. With over 130 years of experience in heat exchanger design and manufacturing, Alfa Laval has built a strong reputation in the industry.

Alfa Laval offers a wide range of heat exchangers, making it easy to select and apply solutions across various industries.

Material Selection:

- A variety of heat exchanger plates are available, including Stainless Steel 304, Stainless Steel 316, Titanium, and corrosion-resistant alloys. These materials are compatible with different fluids and environmental conditions.

Structural Design:

- Plate thicknesses range from 0.4 mm to 0.8 mm, featuring various embossed patterns. This allows customization to meet the specific requirements of different industrial applications.

3. Advantages of Alfa Laval Heat Exchangers

Optimized Heat Transfer Process

Alfa Laval heat exchangers are engineered with cutting-edge technology. The use of thermodynamically optimized plates enhances heat transfer efficiency. The thin, embossed metal plate structure facilitates effective thermal exchange while reducing pressure drop and energy consumption.

Key Features of Alfa Laval Heat Exchangers:

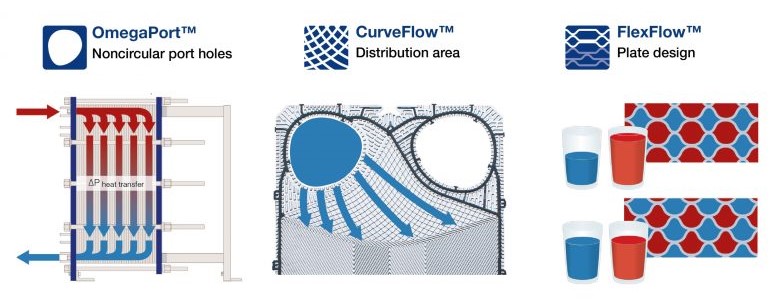

Omega Port™ Noncircular Port Holes

- Prevents flow dead zones within the channel

- Reduces resistance at the connection port while increasing flow resistance in the channel, enhancing heat exchange efficiency

Curve Flow™ Distribution Area

- Maximizes heat transfer surface utilization

- Ensures even fluid distribution within the channel, minimizing fouling and scaling

Flex Flow™ Plate Design

- Suitable for applications with varying flow rates

Reduces fouling in both fluid channels

4. Versatile Applications Across Various Industries

Alfa Laval heat exchangers are designed to withstand high pressure and temperature conditions, making them adaptable to a wide range of industrial requirements. Plate heat exchangers are applicable across numerous industries, from HVAC heating and cooling to food processing, chemical, and oil & gas industries.

Common applications of Alfa Laval heat exchangers include:

- Refrigeration & HVAC Industry: Condensers, evaporators, central chiller systems

- Marine Industry: Coolers, heat exchangers for semiconductor applications

- Food Processing Industry: Food handling, dairy production

- Energy Industry: Turbine cooling, moisture separation

- Mechanical Industry: Engine cooling, hydraulic oil cooling

Additionally, heat exchangers are used in pharmaceutical, beverage, and chemical industries, among others.

Energy Savings and Environmental Protection

With superior heat transfer efficiency, Alfa Laval heat exchangers help conserve energy and reduce CO2 emissions, making them significantly more environmentally friendly compared to traditional solutions. Furthermore, Alfa Laval focuses on minimizing operational and maintenance costs.

5. Alfa Laval Heat Exchanger Product Lines

- M & T Series: Wide capacity range, high efficiency, design pressure up to 30 bar, operating temperatures up to 180°C

- TL Series: Optimized for low approach temperature applications, flow rate range: 5 to 600 l/s

- TS Series: Optimized for steam heating applications, high-performance gaskets ensuring stability and extended lifespan

6. Where to Buy Genuine Alfa Laval Heat Exchangers?

To ensure reliability and performance, it is essential to purchase Alfa Laval heat exchangers from authorized distributors or official dealers. These sources guarantee product quality and provide proper maintenance services throughout the operational lifecycle.

- project@gomec.vn

- Hotline & Zalo 0379 586 886

- (+84) 024 3200 8920

- Gomec Vietnam

- Gomec Vietnam

Sustainability Solutions

Dunham-Bush Products

Mitsubishi Electric Products

Related Post

Alfa Laval Gasketed Plate Heat Exchanger – New T21 Model

Heat Recovery From Air Compressors

Heat Recovery From Open Cooling Tower

Ten top tips to keep your gasketed plate heat exchangers in tip top condition

Leave a Reply