- Home / Solutions In Manufacturing / Heat Recovery From Open Cooling Tower

Heat Recovery From Open Cooling Tower

Contents/ Mục Lục

Heat recovery from cooling towers is a key topic in modern buildings. As the Earth warms, climate change and carbon emissions have become global concerns. This raises the question of how to use energy more efficiently. Environmentally friendly solutions and conservation of natural resources are top priorities. Waste heat is essentially wasted energy because heat is generated by burning fossil fuels, LPG, oil, natural gas ỏ electricity. Therefore, by recovering waste heat, we not only save energy and costs but also contribute to environmental protection.

1. How to Recover Waste Heat from Cooling Towers?

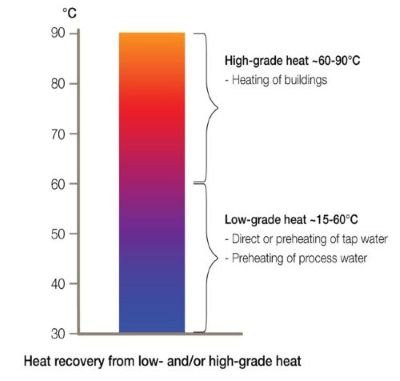

Waste heat energy can be recovered from various sources at different temperature levels and transferred to fluids that require heating.

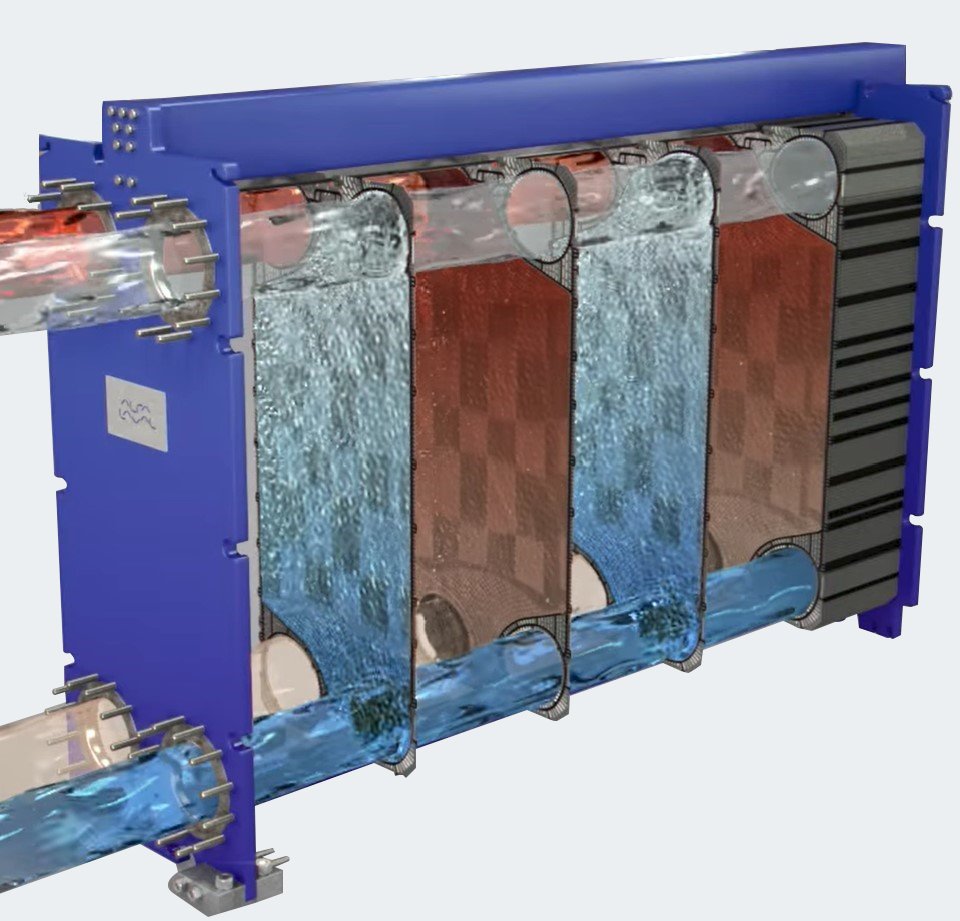

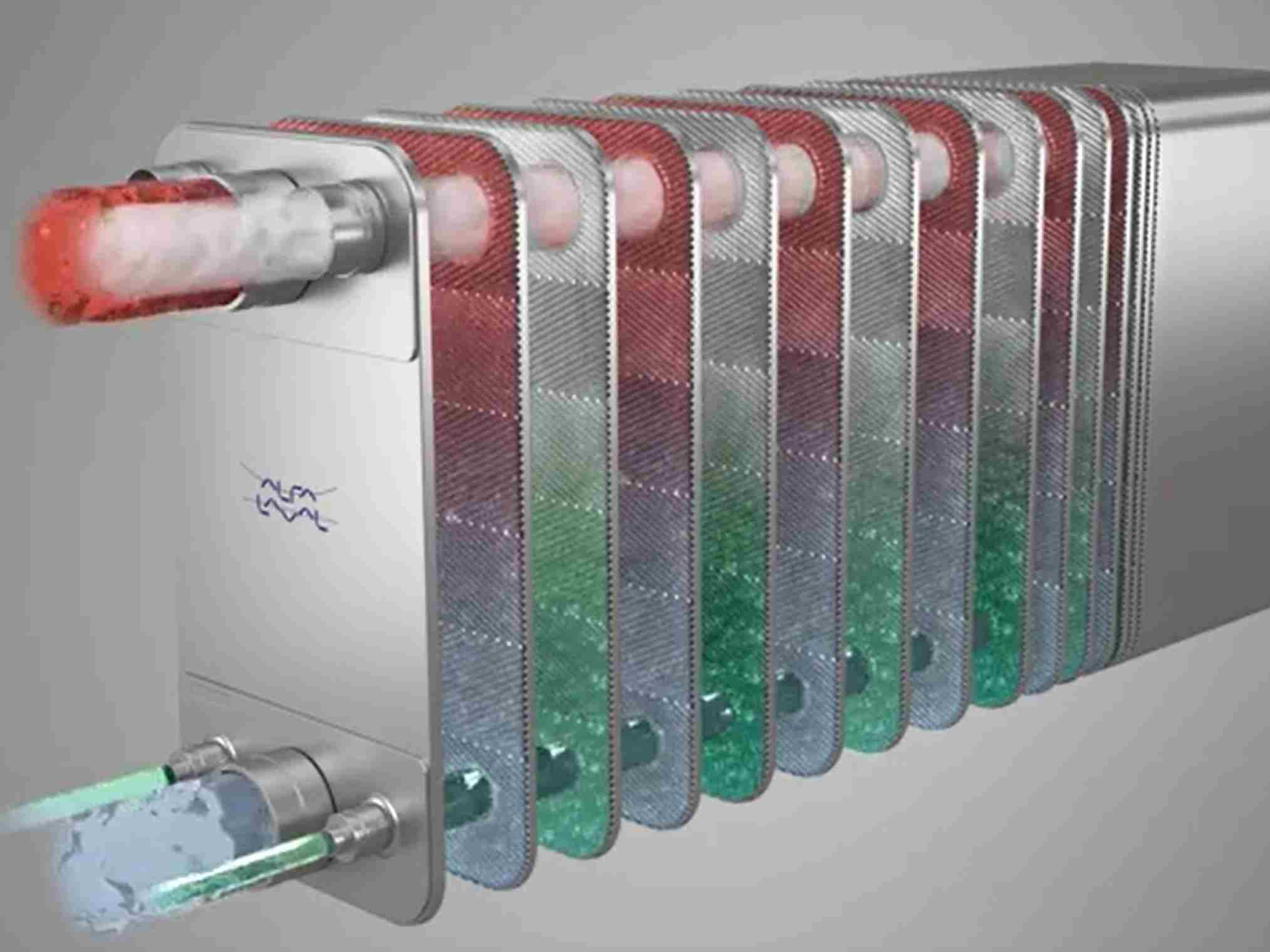

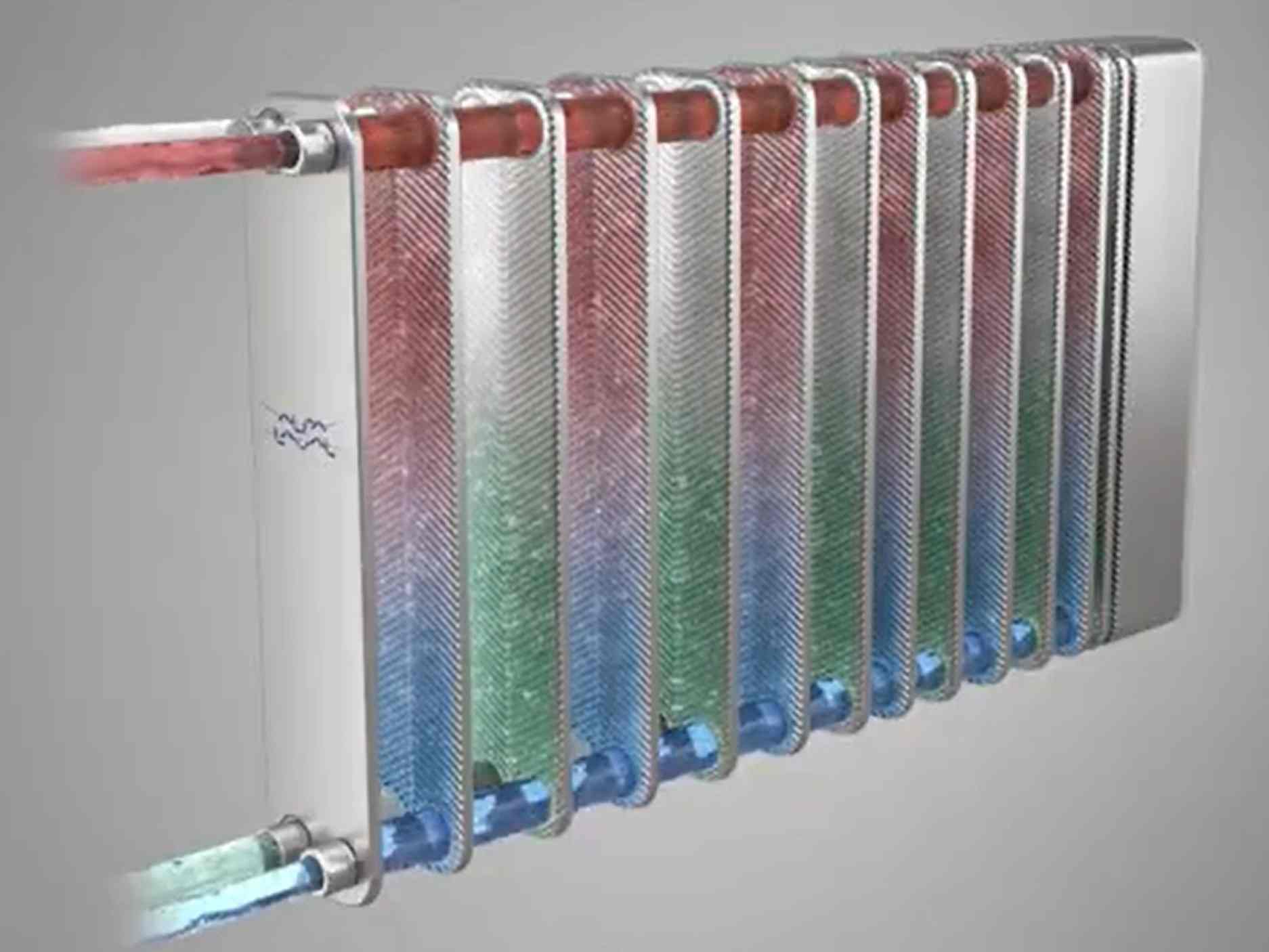

Heating through an intermediate device is achieved using a gasketed plate heat exchanger.

For example, at high temperatures, hot water at 90°C can be used for building heating, while at lower temperatures, cooling tower inlet water at 35°C can be utilized to preheat feedwater before entering boilers or for domestic hot water heating systems.

2. How Cooling Towers Work

Manufacturing industries use heat for various operations, reactions, and production processes. The waste heat generated is then released into the atmosphere through open cooling towers. Similarly, in HVAC applications, many spaces for human occupancy require cooling via air conditioning systems. This results in waste heat being discharged into open cooling towers via the chiller condensers.

Typically, open cooling towers are designed to handle peak temperatures during summer conditions with a ΔT of 5°C. These temperatures can range from 37°C down to 32°C, with a wet-bulb temperature of 29°C. The 37°C temperature can be utilized for boiler feedwater heating when the ambient temperature is between 15–20°C. This means the initial feedwater temperature entering the boiler is also 15–20°C.

3. Heat Recovery from Cooling Towers Using Alfa Laval Plate Heat Exchangers

Alfa Laval plate heat exchangers, designed for counterflow heat transfer, are commonly used in heat recovery applications due to their excellent flow distribution, enabling temperature differentials as low as 1°C. This allows heat recovery from cooling tower water at 37°C, transferring it to the boiler feedwater, raising its temperature from 15-20°C up to 35°C.

However, for optimal economic efficiency in terms of system sizing and payback time, Alfa Laval recommends using a plate heat exchanger with a 2°C temperature differential, meaning the boiler feedwater is heated up to 35°C.

Application Diagram for Cooling Tower Heat Recovery

4. Cost Savings from Heat Recovery in Cooling Towers

Certain costs can be reduced through the application of heat recovery:

- Nearly 40% reduction in boiler fuel costs, as the boiler will heat water from 35°C to 60°C instead of 20°C to 60°C.

- Reduced make-up water consumption due to lower evaporation losses.

- Lower operating costs by reducing the inlet water temperature of the cooling tower.

- Decreased water treatment chemical costs.

Calculation of Cost Savings

A specific example of heat recovery from a 500 RT (1,758 kW) cooling tower, cooling from 37°C to 32°C at a flow rate of 302 m³/h is considered. Assuming partial heat recovery with a flow rate of 50 m³/h, the water entering the cooling tower at 37°C is cooled to 22°C, while the boiler feed water is preheated from 20°C to 35°C. The selected plate heat exchanger has the following parameters:

Heat recovery stream 50 m³/h (13.9 l/s) 37°C → 22°C

Heated Water Stream 50 m³/h (13.9 l/s) 35°C ← 20°C

a. Heat Recovery Calculation (kW)

The recovered heat is equal to the heat required for water heating:

Q = m × c × ΔT (hot side) = m × c × ΔT (cold side)

Where:

Q: Heat recovered (kW)

m: Water flow rate (kg/s)

c: Specific heat capacity of water (kJ/kg°C)

ΔT: Temperature difference (°C)

Q = 13.9 × 4.18 × (35 − 20) = 870.8 kW

b. Energy Savings Calculation (kWh)

Assuming 10 hours of operation per day and 30 days per month:

Energy Saving = 870,8 x 10 x 30 = 261.250 (kW/h /month)

c. Cost Savings Conversion to VND

With an estimated electricity cost of 2,000 VND/kWh, assuming the boiler uses electric resistance heating with 100% efficiency:

Cost Savings = 261.250 x 2000 = 522.500.000 VND/month

d. New return temperature to tower

With a total of 302 m³/hr split as 50 m³/hr at 22°C and 252 m³/hr at 37°C. Hence the overall return cooling tower temperature will be:

(50×22)/302 + (252×37)/302 = 34,5°C

5. Conclusion

With the above benefits, utilizing a plate heat exchanger to recover heat from cooling towers in factories, high-rise buildings, or industrial facilities provides significant cost savings and contributes to environmental sustainability.

Preactice tips: If preheated water cannot instantly be used at the boiler, this water can be stored in a buffer tank to be used at a later stage when needed. The payback period will be reduced if the cooling tower and boiler are placed close to each other, as the piping investment cost will be reduced.

Reference: Heat Recovery Solutions from Air Compressors

- project@gomec.vn

- Hotline & Zalo 0379 586 886

- (+84) 024 3200 8920

- Gomec Vietnam

- Gomec Vietnam

Related Post

Heat Recovery From Air Compressors

Heat Recovery From Warm Wastewater

Fantastic site A lot of helpful info here Im sending it to some buddies ans additionally sharing in delicious And naturally thanks on your sweat