AlfaNova

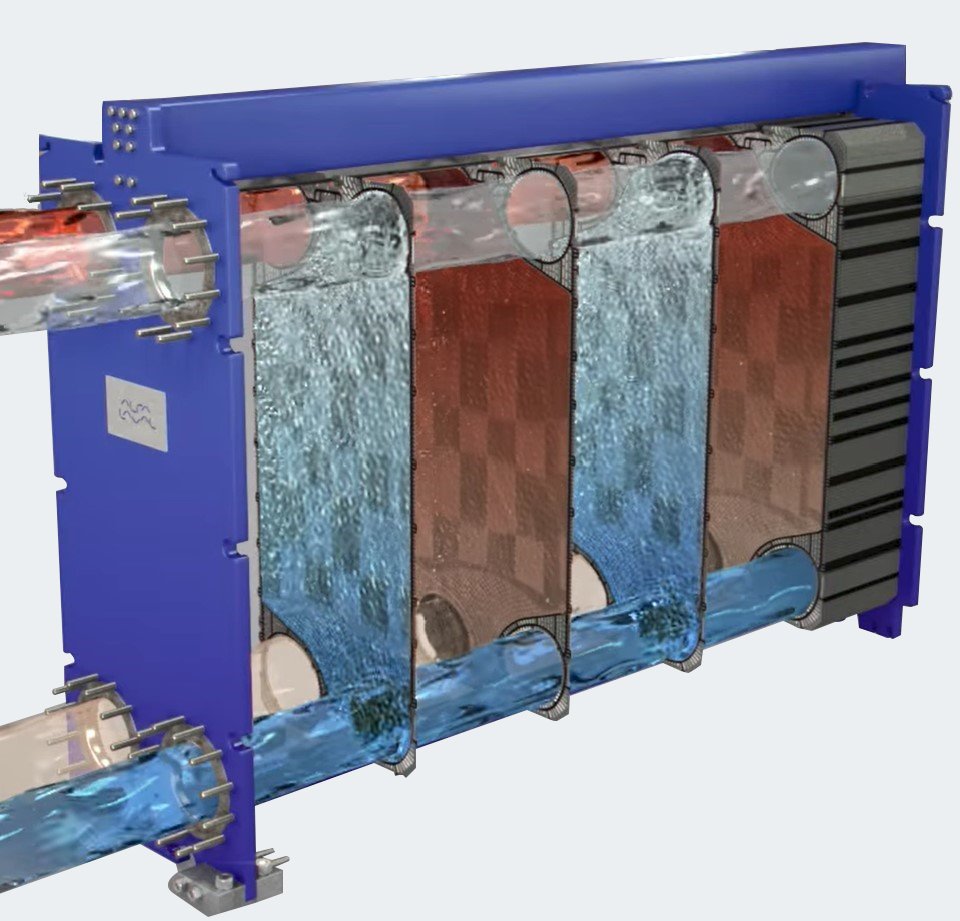

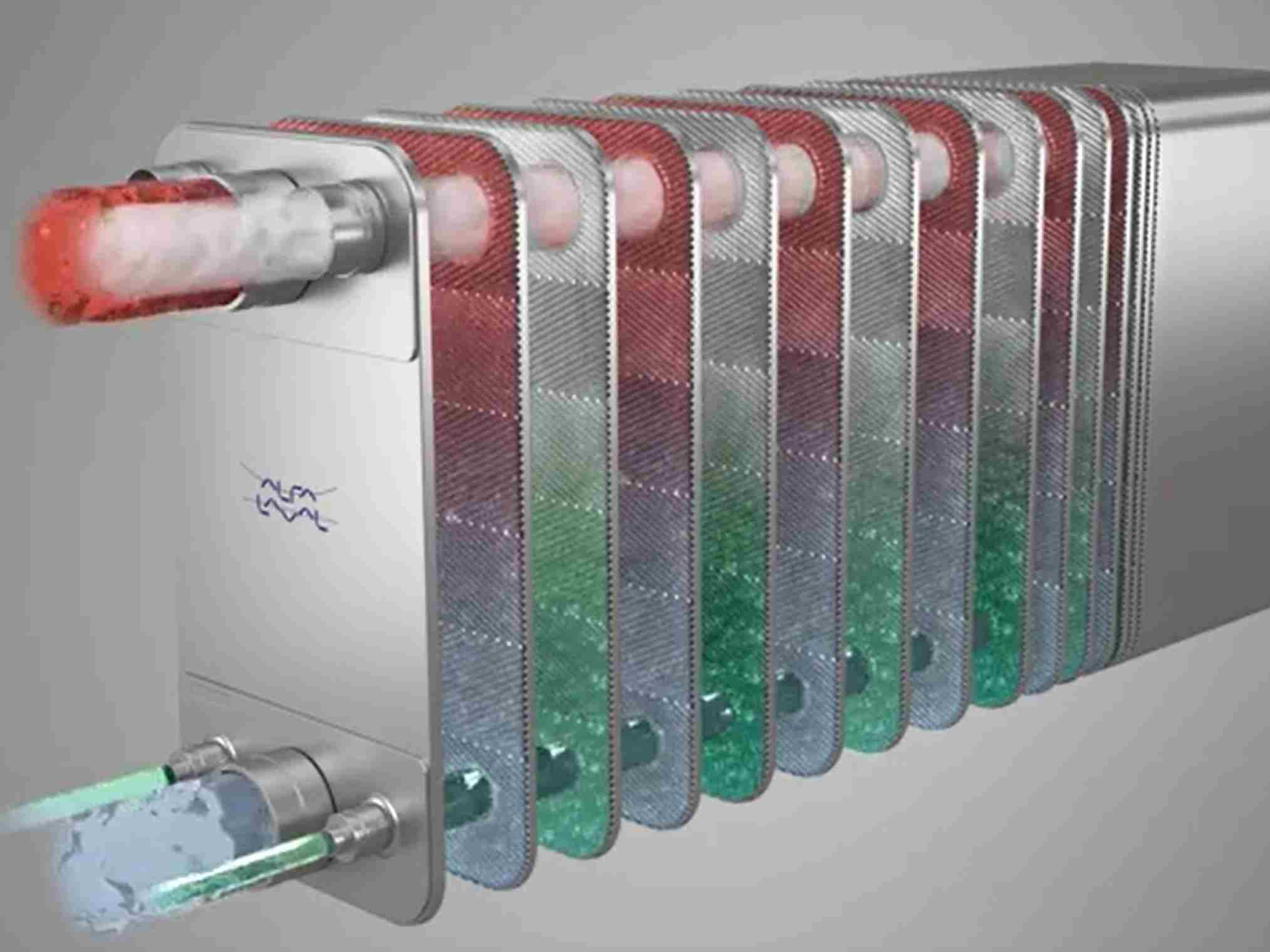

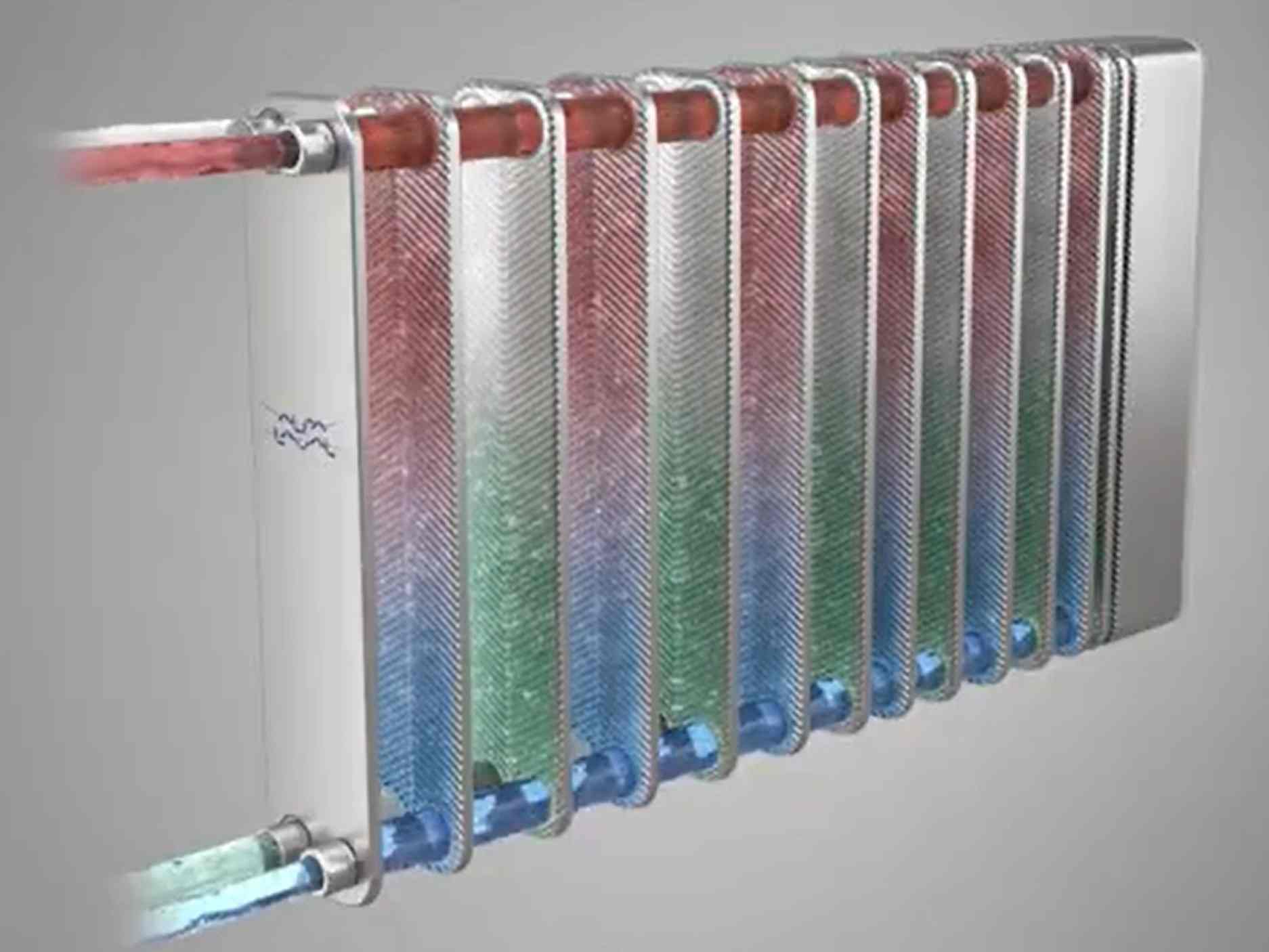

Manufactured with Alfa Laval’s patented AlfaFusion technology, AlfaNova is a heat exchanger consisting of corrugated stainless steel plates bonded together without any copper or nickel. The unique design means that AlfaNova can withstand more extreme temperatures and pressures with greater fatigue resistance than conventional brazed plate heat exchangers. It is also suitable for duties with very high hygiene demands.

AlfaNova

AlfaNova’s unique fusion-bonded manufacturing process provides greater reinforcement for the plate pack, which in turn ensures a higher degree of pressure resistance than that offered by comparable technologies. Additionally, the 100% stainless steel construction makes it possible to withstand temperatures as high as 550°C (1020°F). As a result, the AlfaNova fusion-bonded plate heat exchanger is highly dependable in applications with extreme pressure and/or temperature demands. Use of the same material for all key components also provides high thermal efficiency, in addition to giving the unit mechanical strength equivalent to any fully welded counterpart.

More with AlfaNova

![]() An optimal solution for hygienic applications such as tap water systems

An optimal solution for hygienic applications such as tap water systems

![]() Copper-free design is suitable for use with ammonia refrigerant and for clean water refrigeration chiller applications

Copper-free design is suitable for use with ammonia refrigerant and for clean water refrigeration chiller applications

![]() Load distribution across many contact points secures excellent resistance to pressure fatigue

Load distribution across many contact points secures excellent resistance to pressure fatigue

![]() AHRI-certified for reliable thermal performance in a range of HVAC applications

AHRI-certified for reliable thermal performance in a range of HVAC applications

![]() Available with marine classification for use in a range of LPG/LNG duties, due to wide temperature range and copper-free construction

Available with marine classification for use in a range of LPG/LNG duties, due to wide temperature range and copper-free construction

Alfa Laval AlfaNova fusion-bonded plate heat exchanger

Please contact GOMEC Vietnam for technical specifications that meet specific design requirements.

| Catalog | Link |

| alfa-laval-product-leaflet-en-che00046 | View & Download |

Please contact GOMEC Vietnam for a catalog with models that meet specific design requirements.